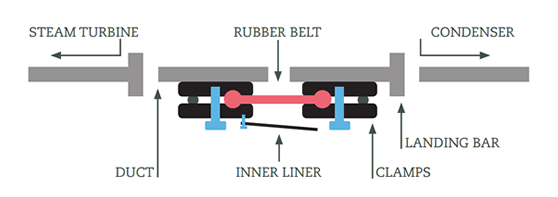

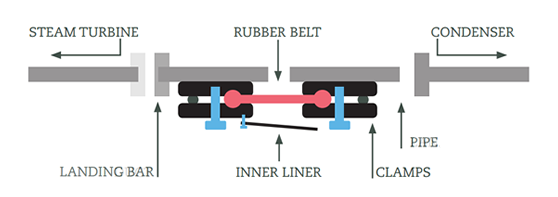

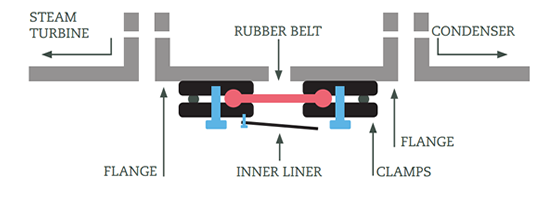

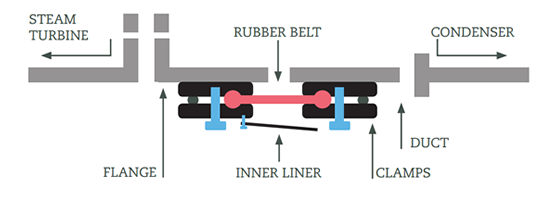

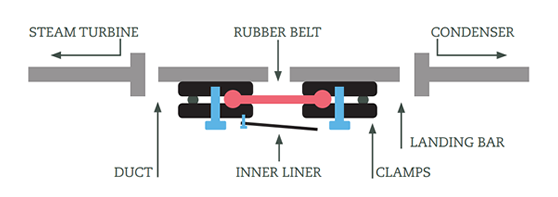

The Dog Bone Type Expansion Joint is used as flexible connection between Turbines and Condensers. This turbine exhaust expansion joint is used as a flexible connection in power plants and it is the most widely used turbine to condenser expansion joint in use.

One of the main functions of the Dog Bone Expansion Joint is to absorb the differential thermal expansion between the steam turbine and the condenser while imparting minimal forces and moments on the turbine exhaust flange. Steam turbines come in a variety of exhaust configurations such as down exhaust, axial exhaust and top exhaust. Each configuration has unique design and performance requirements for the expansion joint. The expansion joint must perform satisfactory under a wide range of operating conditions to ensure reliable operation of the turbine condenser system.

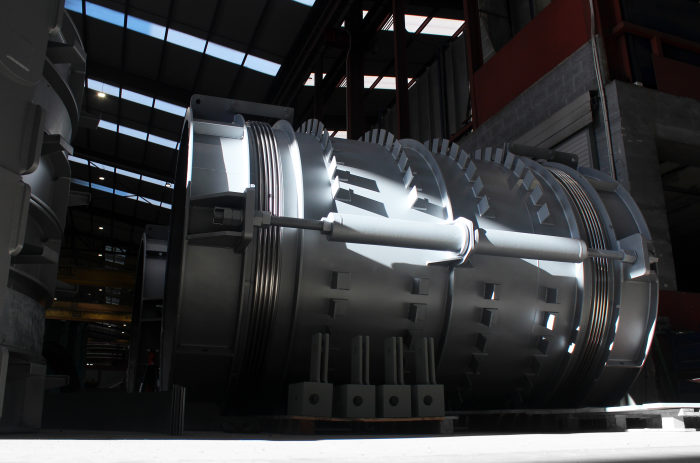

MACOGA provides the highest Quality Dog-Bone Type Expansion Joints.