Bellows materials of construction can be stainless steel, carbon steel, nickel alloys, rubber or even a composite material.

Stainless Steel Metal Expansion Joints are a bellows-type device used for:

Stainless Steel Bellows are used today in almost all industrial sectors worldwide:

Stainless Steel and other metal bellows are designed, manufactured and tested in accordance with:

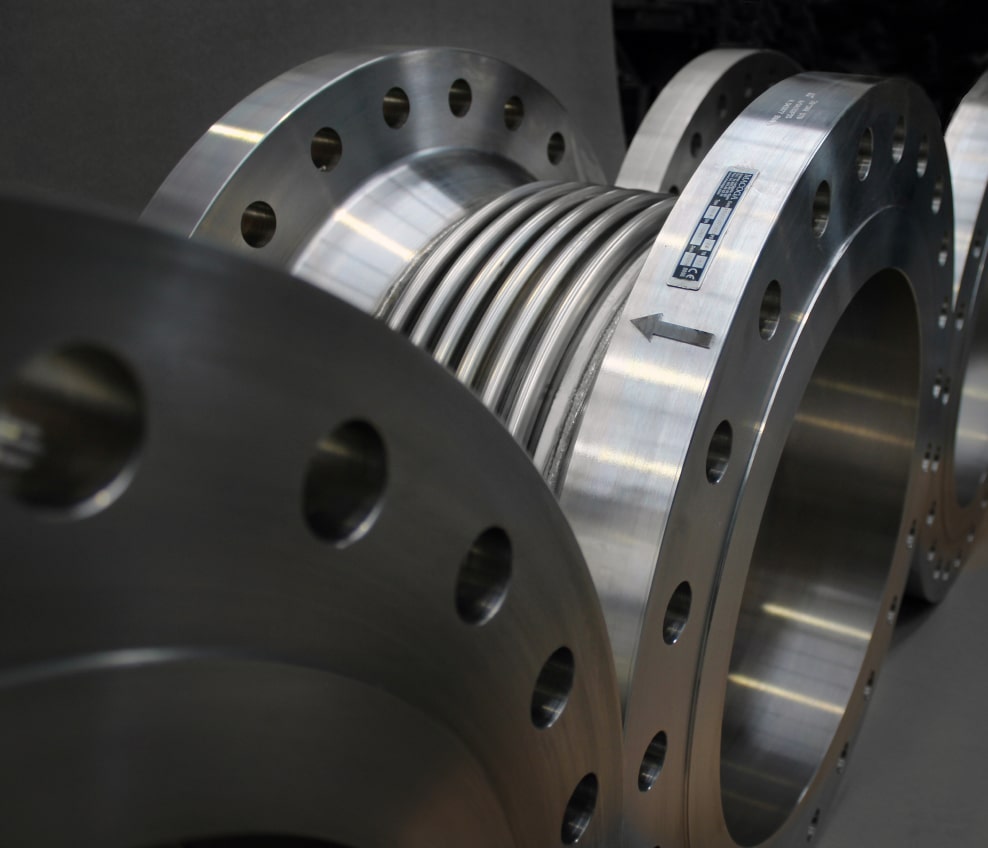

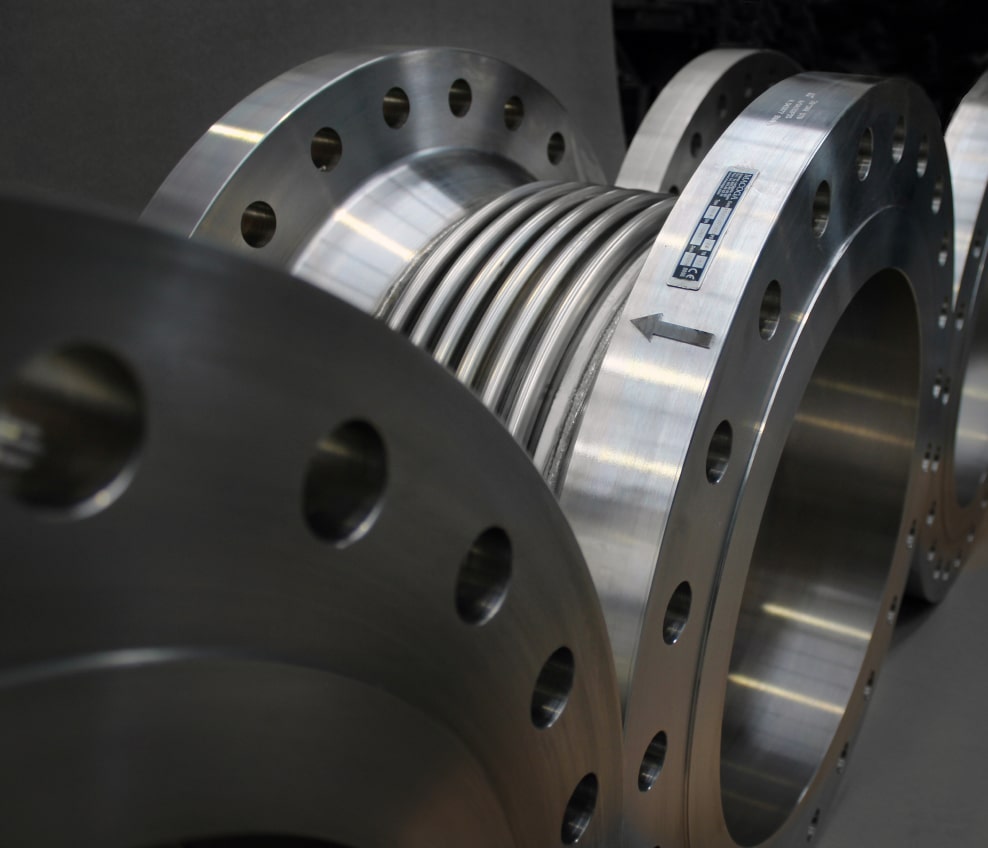

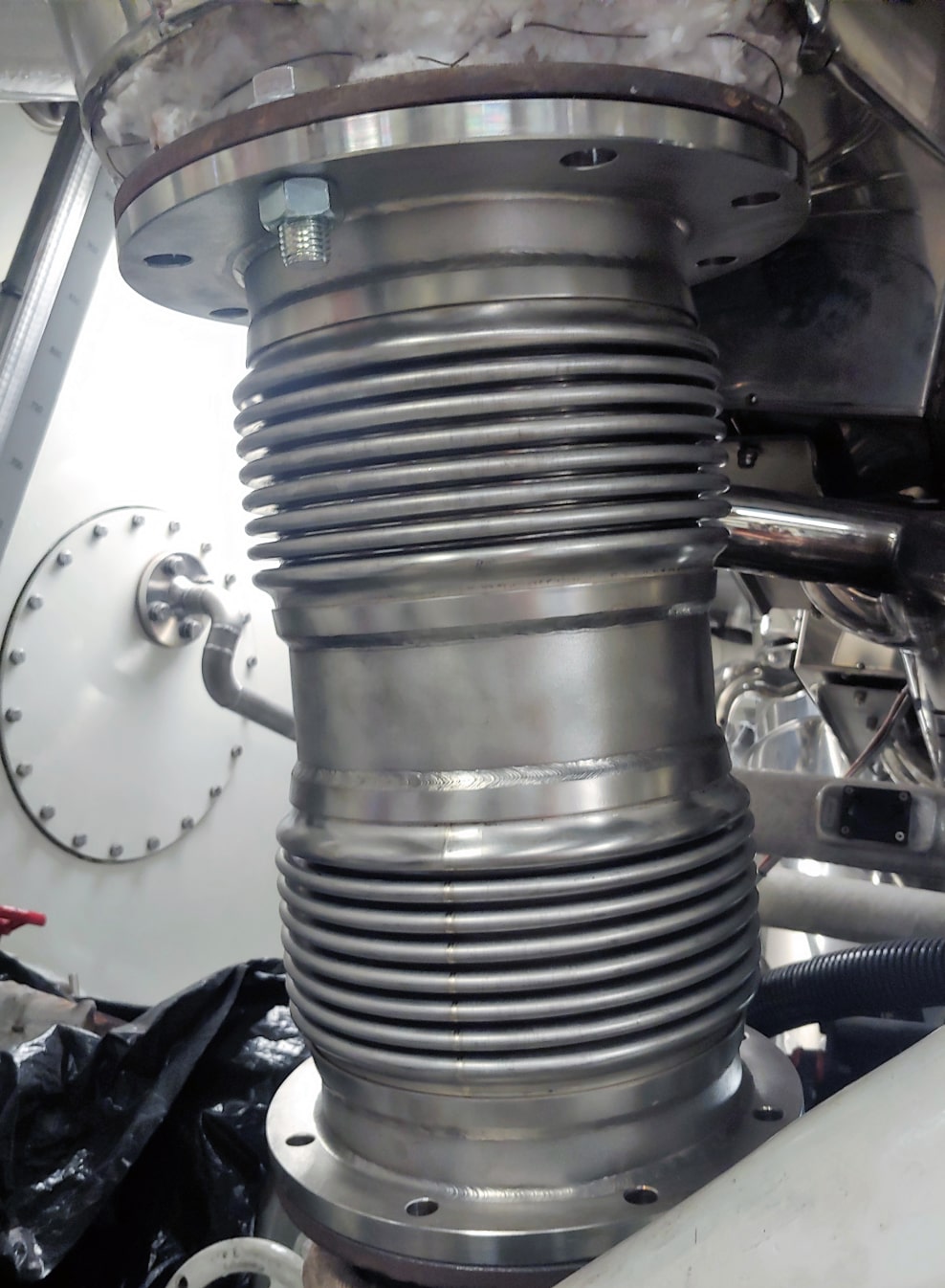

Circular Expansion Joints are manufactured with single or multiple ply with a diameter ranging from 15 to 10000 mm.

Rectangular Expansion Joints which, with limitless dimensions, can be supplied with different convolution and corner types.

Our manufacturing range includes Stainless Steel and other materials Circular Expansion Joints of the following types:

Rectangular Expansion Joints which, with limitless dimensions, can be supplied with different convolution and corner types:

The essential component of an Expansion Joint resides in the degree flexibility of its bellows and this depends upon the design of its convolution and the materials used during the production process.

The choice of metals to be used in manufacturing the bellows, being the basic component of the Expansion Joint, is made taking the following criteria into account:

The tables shows the materials mostly used to produce our bellows:

| Name | ASTM | UNS | EN | |

|---|---|---|---|---|

| 304 | 304 | S30400 | 1.4301 | Austenitic General Service |

| 304L | 304L | S30403 | 1.4306 | |

| 316 | 316 | S31600 | 1.4401 | |

| 316L | 316L | S31603 | 1.4404 | |

| 316H | S31609 | 1.4401/1.4919 | - | |

| 316Ti | 316Ti | 1.4571 | 1.4571 | |

| 321 | 321 | S32100 | 1.4541 | |

| 904L | 904L | N08904 | 1.4539 | |

| 254 SMO | S31254 | S31254 | 1.4547 | |

| 304H | 304H | S30409 | 1.4948 | Austenitic Heat Resisting |

| 321H | 321H | S32109 | 1.4878 | |

| 309S | 309S | S30908 | 1.4833 | |

| 310S | 310S | S31008 | 1.4845 | |

| 253 MA | S30815 | S30815 | 1.4835 | |

|

Stainless steel grades

254 SMO and 253 MA are trademarks of Outokumpu Stainless |

||||

| Name | UNS | EN |

|---|---|---|

| Inconel 600 | N06600 | 2.4816 |

| Monel 400 | N04400 | 2.4360, 2.4361 |

| Inconel 625 | N06625 | 2.4856 |

| Inconel 625LCF | N06625 | 2.4856 |

| Incoloy 800 | N08800 | 1.4876 |

| Incoloy 800H | N08810 | 1.4958 |

| Incoloy 825 | N08825 | 2.4858 |

| Hastelloy C4 | N06455 | 2.4610 |

| Hastelloy C-22 | N06022 | 2.4602 |

| Hastelloy C-276 | N10276 | 2.4819 |

|

Nickel Alloys

Inconel, Monel & Incoloy are trademarks of Special Metals Corporation. Hastelloy is a trademark of Haynes International, Inc. |

||