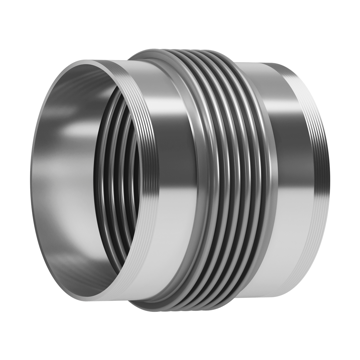

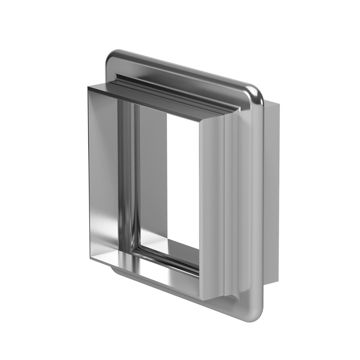

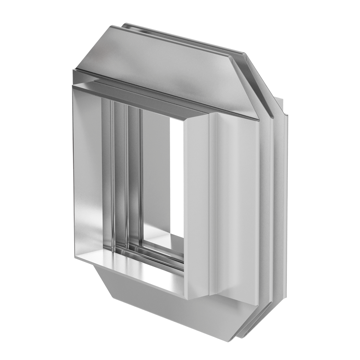

This model is used in cases of high internal pressures and/or equalizing the movement among all the corrugations.

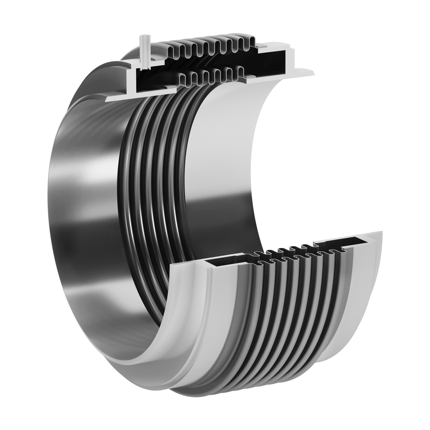

The system involves the use of reinforcement or equalizing rings located around the outside of the convolution thus preventing the bellows being forced out of shape due to the high pressures.

Equalizing and Reinforcing Rings are devices used on some expansion joints fitting snugly in the roots of the convolutions. The primary purpose of these devices is to reinforce the bellows against internal pressure and equalize the movement among all the corrugations.

Equalizing and reinforcing rings are made of carbon steel, stainless steel or other suitable alloys.

Reinforcing rings are usually "T" shaped in cross section and equalizing rings are generally fabricated from tubing or solid round bars of carbon steel, stainless steel, or other suitable alloys.

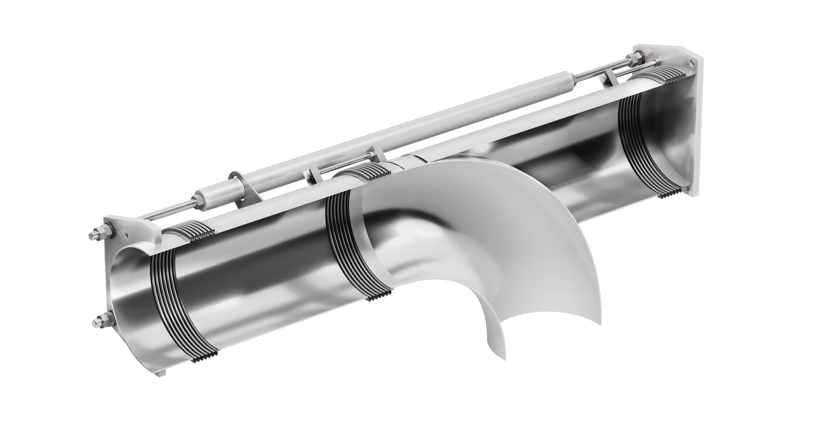

Bellows including reinforcing or equalizing rings can be incorporated to any type of Expansion Joint (Axial, Lateral, Angular, etc.)

More information