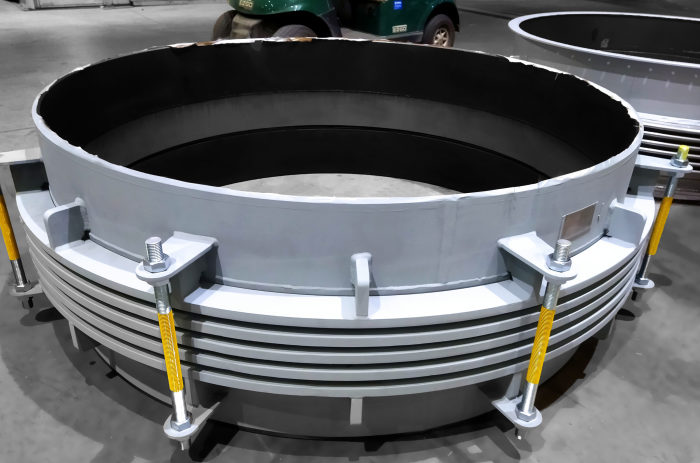

ASME R Stamp Clamshell installation at Aluminium Plant in Europe

MACOGA On-Site Team has successfully completed the installation of a Reinforced Clamshell Expansion Joint ASME R Stamped at an Aluminium Plant in Europe.

The clamshell was designed and manufactured to meet the highest standards of quality, safety and performance and the installation was completed on time and in accordance with ASME and customer's requirements.

Design codes and specifications

- EJMA latest edition

- ASME Code

Type MRR Clamshell

- Size 1800 mm (72”)

- Bellows material A/SA 240 Tp 321

- Design temperature +190 °C (+374 °F)

- Design Pressure 8,31 BARg/FV (120,53 PSIg/FV)

- Test Pressure 12,45 BARg (180,57 PSIg)

The ASME R Stamp Clamshell installation process is a complex one, and it is essential that it is done correctly. Only highly experienced and qualified technicians should be employed to carry out this type of installation.

The process involves a number of steps, including the positioning of the clamshell, welding of the convolutions and other components, and finally a thorough inspection to ensure they are up to the standard specified by the ASME R stamp. The installation is also subject to specific regulations and guidelines set out by the ASME, which must be strictly followed.

The R Stamp is a sign of quality assurance, as the manufacturer or repairer has demonstrated the ability to meet the requirements of the ASME Boiler and Pressure Vessel Code.

More information https://www.macoga.com/en/expansion-joints-for-specific-applications/clamshell