Ensuring confidence in Expansion Joints during product design

Technological advances and changes in most industrial sectors (power generation, oil & gas, aerospace, petrochemicals, etc.) impose greater demands on products and therefore on the engineering process.

Products and experiences are becoming more and more complex, while performance and quality objectives are becoming more and more demanding.

At MACOGA, our engineers are equipped with the necessary tools to gain insight into the key factors for quality and performance at an early stage of product development. Digital prototyping coupled with digital analysis and simulation allows our engineers to virtually create and analyze an Expansion Joint and all its components in their operating environment.

Our engineers possess a diverse skill set to execute complex problem solving in a straightforward manner. We use 3D CAD, finite element analysis, fluid dynamics, thermal analysis, structural analysis, tolerance analysis and materials science to perform modelling and calculations as well as to create physical prototypes.

Computer Aided Design (CAD) Software

A 3D CAD allows us to build 3D models of parts and assemblies. Our CAD tools also have direct integration into an FEA (Finite Element Analysis) package so we can combine seamlessly design and analysis.

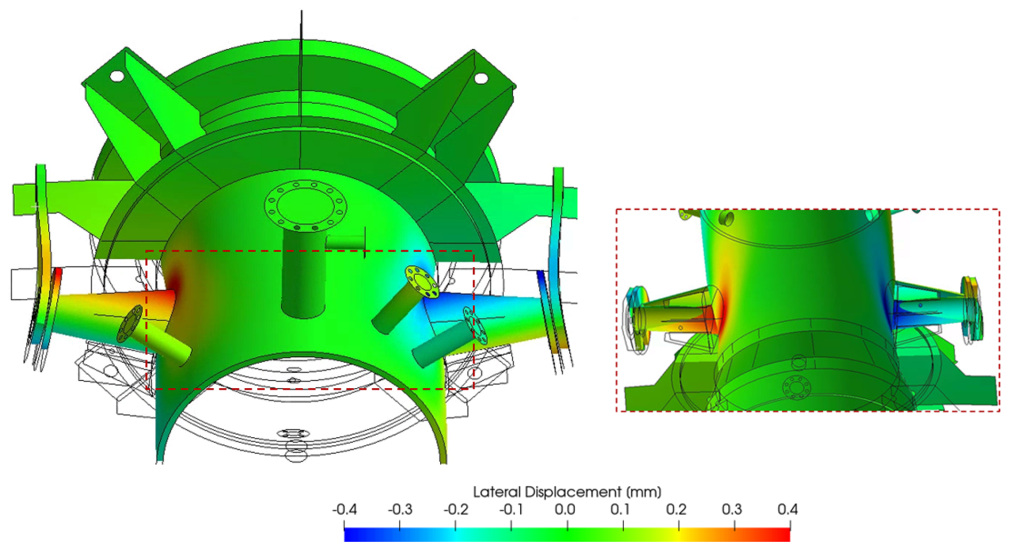

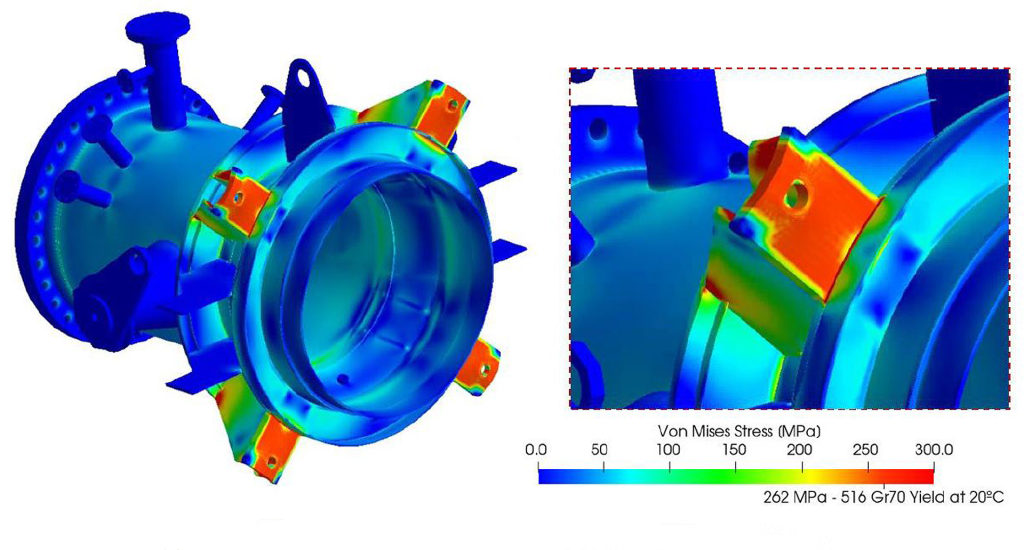

Finite Element Analysis

Structural analysis is done with Finite Element Analysis (FEA). The Finite Element Analysis software allows us to analyze stresses and deflections in complex structures.

Computational Fluid Dynamics

Using engineering simulation software, we access sophisticated fluid dynamics capabilities to analyze and solve problems that involve fluid flows.

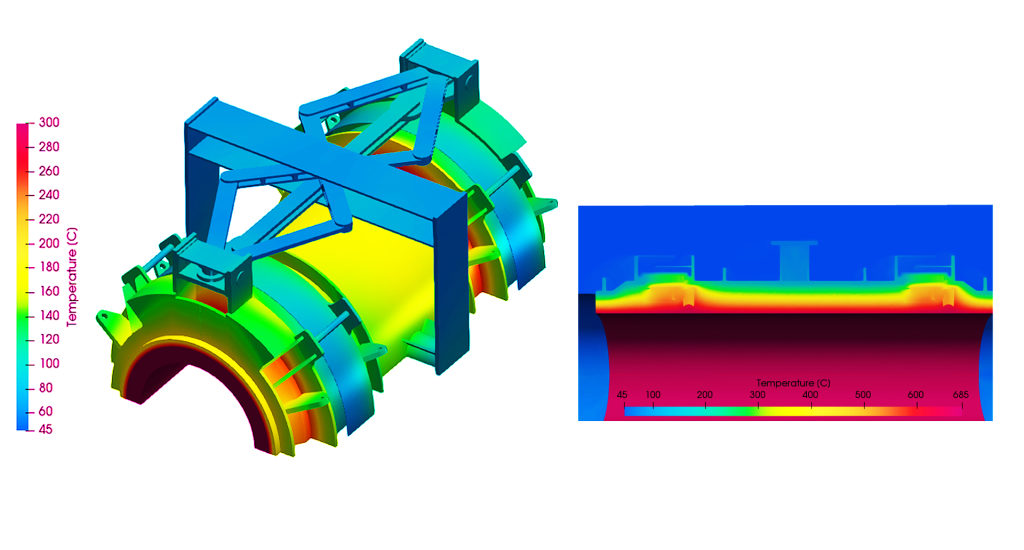

Thermal Analysis

We perform thermomechanical and heat transfer analyses, so we can predict the behavior of our Expansion Joints under the influence of temperature.

Analysis of vibrations and frequency

We carry out vibrations and frequency analysis based on computerized simulations that allow us to evaluate and validate a design.