FCC Expansion Joints for Middle East Refinery as per UOP specifications

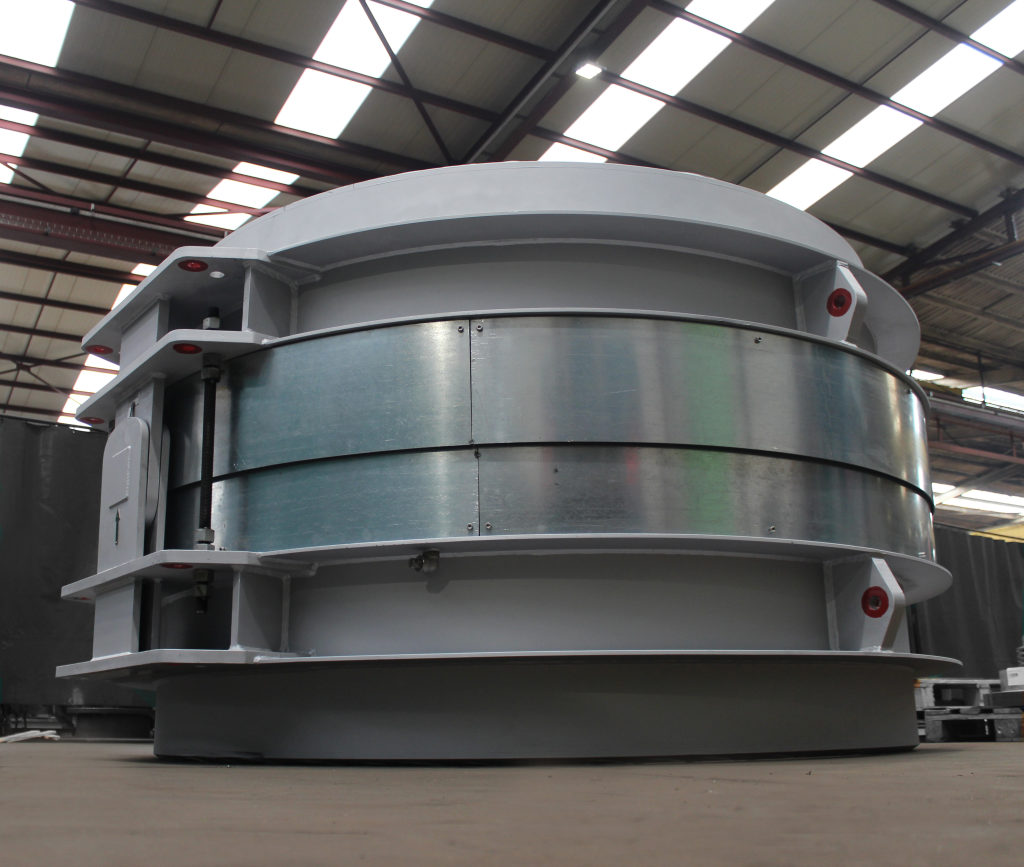

We have successfully completed the design, manufacturing and testing of High-Tech FCC Expansion Joints for a large refinery located in the Middle East.

Design Codes and Specifications:

- ASME B31.3 Edition 2016

- EJMA 10th Edition 2015

- ASME General Standards

- UOP Standards

Main mechanical design, parameters and features of the expansion joint supplied are:

MWA FCC Expansion Joint

- DN 2400 mm - Length: 620 mm

- Monitored Bellows in SB-443 N06625 Gr.1 LCF, 2 ply testable

- Packed system

- Pipe in SA516Gr.70N

- Hex-mesh in Grade 304H,

- Erosion resistant castable AA-22S

- U-anchors in Grade 304H annealed after forming

- Hose braid in Grade 309 with internal woven wire mesh in Grade 309

- Design pressure: 0,16 barg

- Bellows design temperature: 538 °C

- Pipe-line design temperature: 343 °C

- Medium temperature: 729 °C

MWP Hinged FCC Expansion Joint

- DN 2400 mm - Length: 1500 mm

- Monitored Bellows in SB-443 N06625 Gr.1 LCF, 2 ply testable

- Packed system

- Pipe in SA516Gr.70N

- Hex-mesh in Grade 304H,

- Erosion resistant castable AA-22S

- U-anchors in Grade 304H annealed after forming

- Hose braid in Grade 309 with internal woven wire mesh in Grade 309

- Refractory lining RS-17EC

- V-anchors in Grade 304H material

- Design pressure: 0,16 barg

- Bellows design temperature: 538 °C

- Pipe-line design temperature: 343 °C

- Medium temperature: 729 °C