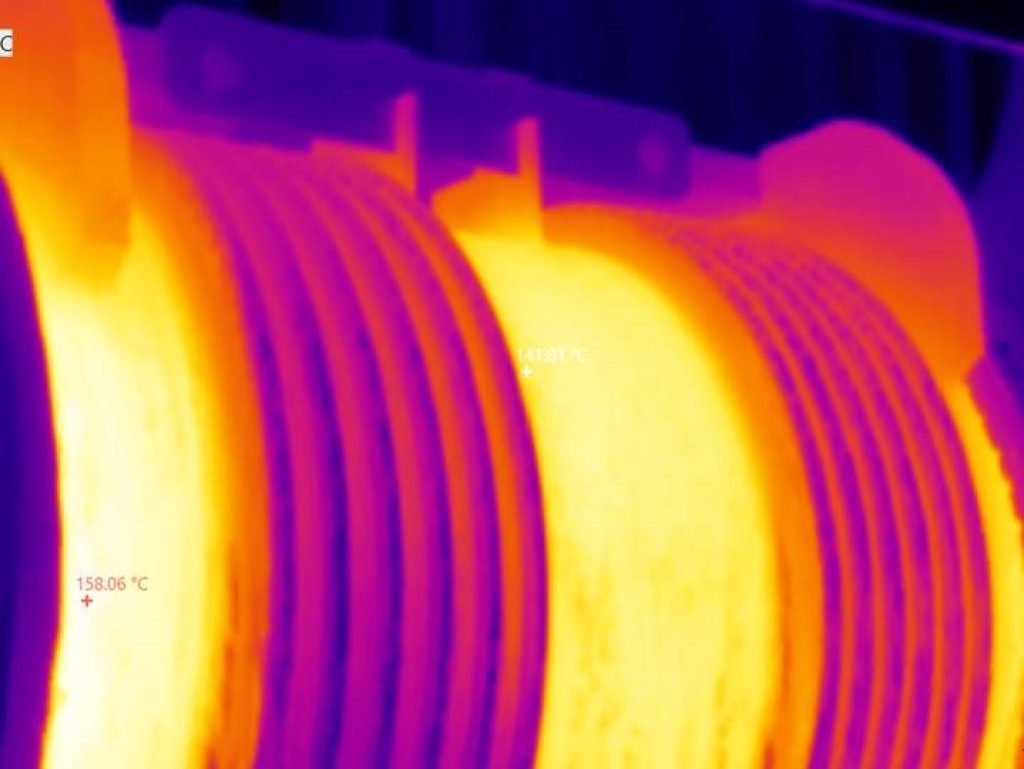

Hot Inspection of FCC Expansion Joints in a Middle East Refinery

We provide on-site inspection of FCC Expansion Joints well in advance your next planned outage, during the beginning stages of a turnaround to aid in planning and expediting the turnaround, during installation of new Expansion Joints, during start-up and periodical inspections.

The FCC (Fluid Catalytic Cracking) unit, is a huge piece of equipment used to convert heavy crude oil into marketable fuel products like gasoline and consists of several pipes, cyclones, Expansion Joints and reactor vessels, all of which need to be inspected periodically to ensure the unit is safe for continued use.

On this occasion, one of our FCC Expansion Joints specialists carried out an in-depth inspection of eleven FCC Expansion Joints in operation at a refinery in the Middle East.

MACOGA staff spent five days at the refinery collecting data from the FCC Unit Expansion Joints during operation.

Conditions during the inspection were difficult. Despite these challenges, our specialist was able to collect all the data needed for the unit inspection and provide the refinery with all the necessary information to help plan, strategize, and execute a highly successful turnaround.

Maintenance and inspection functions in a refinery are critical elements for safe and reliable operation of the plant and play a key role in the effective achievement of the desired production target and the profitability of the refinery.

MACOGA on-site staff can provide you:

- Installation guidance for new FCCU Expansion Joints

- Inspection in cold conditions (plant shutdown)

- Inspection in hot conditions (plant in operation)

- Periodical Inspections

- Maintenance and refurbishment

- Problem resolution

- Immediate response to site inspections needs

- Quick-turn expansion joint replacement during shutdowns and turnarounds