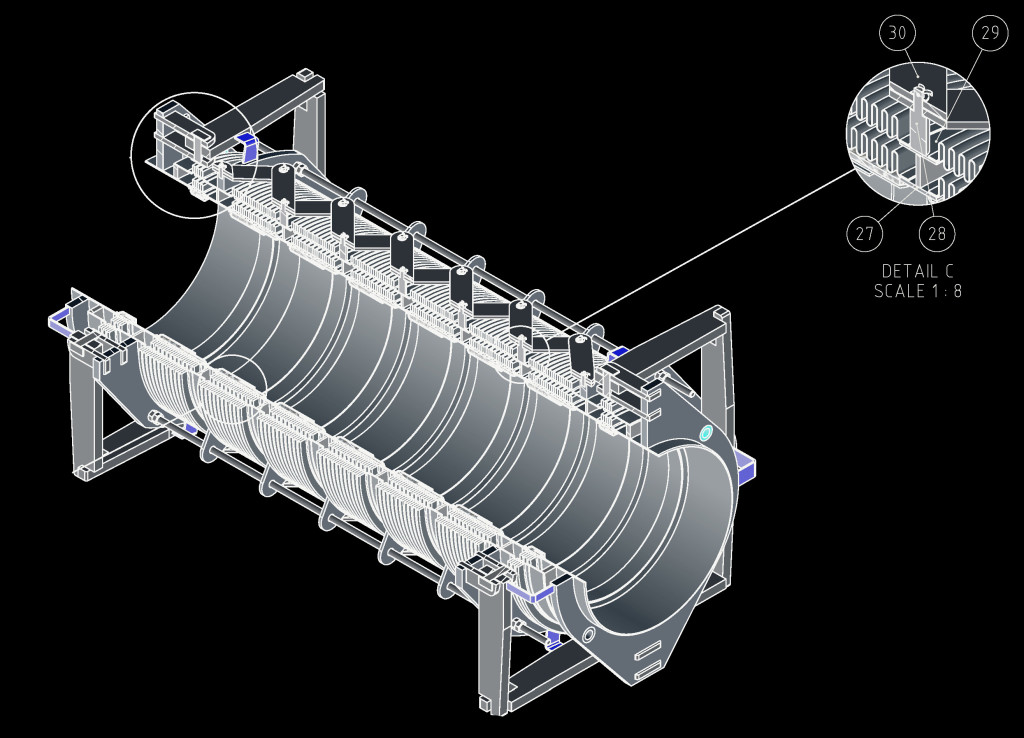

Jacketed and Pantographic Expansion Joint for steel plant in Europe

We have completed the engineering, manufacturing, testing and shipping of a Jacketed and with Pantographic Linkage Expansion Joint for one of the largest steel plants in Europe.

Jacketed Expansion Joints are used in a set of circumstances such as when regular insulation is not sufficient and when the main fluid must be kept at a fixed temperature or simply for security reasons. This model involves using two bellows, one on the inside and one on the outside.

The pantographic linkage distributes the large axial movement between bellows.

Additionally, the Expansion Joint incorporates a double gimbal system that allows the expansion joint to take multiplane lateral movements while restraining the pressure thrust.