Refractory Lined + ASME U Stamped Expansion Joints for Ammonia Plant in North Africa

Commercial fertilizer production challenges engineers when it comes to high pressures, temperatures, and corrosion resistance. The specific environment requires special (custom) designs and high-quality corrosion resistant materials. MACOGA is the specialist in this field and has developed a wide range of Expansion Joints that are being successfully used in the fertilizer production process.

Our client located in North Africa produces liquid Ammonia and utilizes KBR’s latest and commercially proven KBR Advanced Ammonia Process (KAAP) technology.

Industry / Application: Ammonia Plant / Chemical Industry

- Type: Type MRR Reinforced

- Qty: 1 unit

- Size: 1150 mm

- Design Code: ASME VIII Div.1, APP. 26, Edition 2019

- Stamp : ASME U

- Bellows material: SB443 N06625 Gr.1

- Working pressure: 43,42 BARg (629,73 PSIg)

- Working Temperature: +482 °C (+899,60 °F)

- Hydrostatic Test: 63,00 BARg (913,74 PSIg)

- Medium: Hydrogen + Hydrocarbons

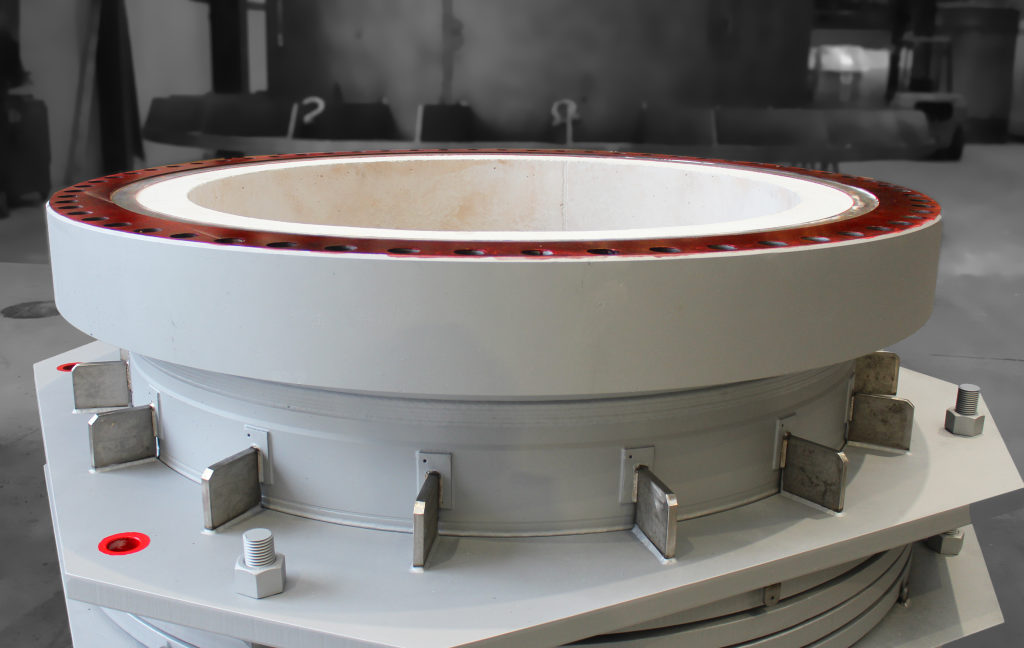

- Type: Type MRR Reinforced

- Qty: 1 unit

- Size: 1524 mm

- Design Code: ASME VIII Div.1, APP. 26, Edition 2019

- Stamp : ASME U

- Bellows material: SB443 N06625 Gr.1

- V-Anchor: Grade ALLOY 601

- Refractory: GREENCAST 94 PLUS

- Working pressure: 41,30 BARg (599,01 PSIg)

- Working Temperature: +427 °C (+800 °F)

- Hydrostatic Test: 63,00 BARg (913,74 PSIg)

- Medium: Hydrogen + Hydrocarbons

In every industrial production process of fertilizers, manufacture of by-products, base chemicals, components and in all linked facilities, the installation of Rubber and Metal Expansion Joints is necessary to absorb the thermal expansion of the pipes and the vibrations produced by the associated equipment (pumps, etc.).