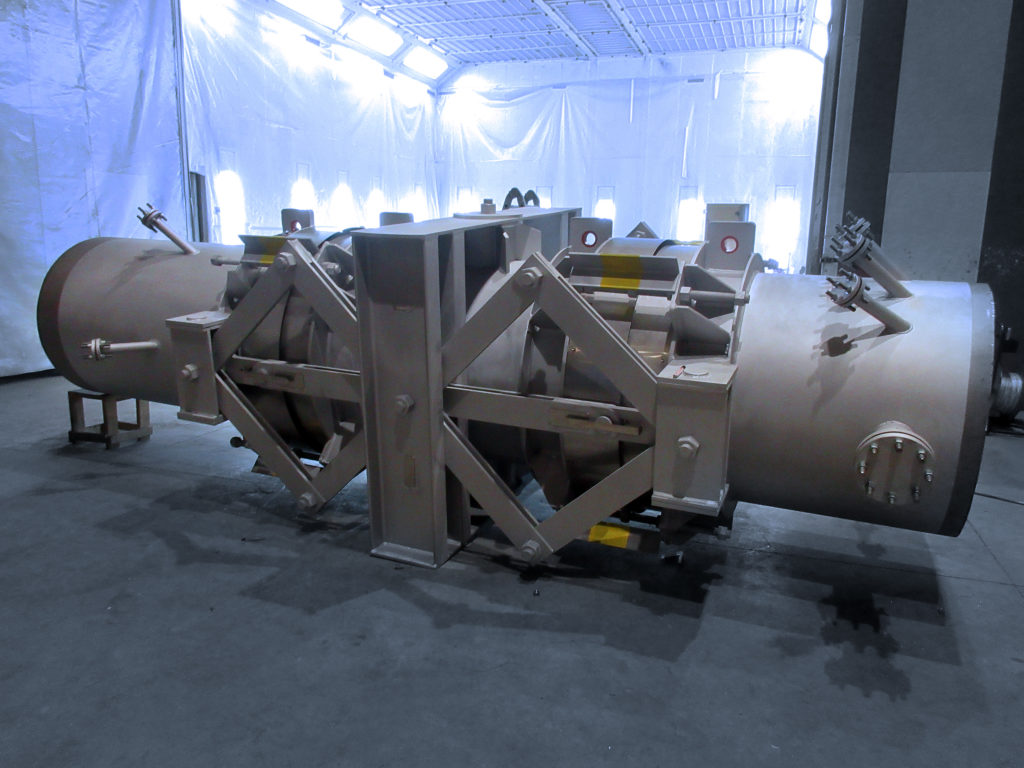

FCCU Regenerator Spent Catalyst Expansion Joint for a Refinery in the United States

A highly sophisticated FCCU Regenerator Spent Catalyst Expansion Joint has been positively designed, manufactured, tested and shipped to a refinery in the United States.

Design Codes and Specifications:

- UOP specifications

- EJMA latest edition

- ASME Code

Main mechanical design, parameters and features are:

- Universal Expansion Joint – Pantograph design

- DN 1500 mm (42”) - Length: 5029 mm

- 2 ply testable bellows in SB-443 N06625 Gr.1 LCF

- Pipe line made in SA516 Gr. 70N

- Hexagonal mesh in Grade 304H

- Refractory linning type Resco RS-17 EC

- Internal bellows packing system

- Design conditions: 5,76 BARg (83.5 PSIg)

- 343 °C / 650 °F (Shell Design Temperature)

- 1450/650 °F (Process), 1000 °F (Bellows) & 100/-20 °F (ambient)

- 788/343 °C (process), 538 °C (bellows) & 38/-29 °C (ambient)

- Medium: Catalyst