District heating

District heating systems are widely used in large cities. Those are a supply system for sanitary hot water and heating. Their main characteristic is that the heat or thermal energy is produced in a power plant and is distributed through a network of urban pipes (normally placed underground) to the points of consumption.

District heating with combined heat and power is the cheapest method of cutting carbon emissions and has one of the lowest carbon footprints of all fossil generation plants.

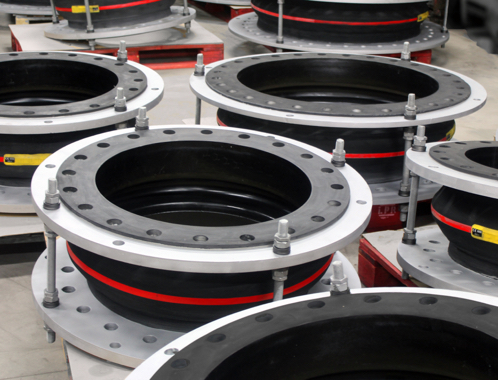

These large piping systems in combination with the temperature changes in the system during start-up, service and shutdowns, resulted in the development of a specific type of expansion joints specially designed to deal with the characteristics of this service ensuring a large lifetime and reliability in operation.

Features and advantages

- Absorb large axial displacements, which lead into the use of bellows with high degree of flexibility and movement absorption capabilities.

- External Protection, granted by the external protective cover, which allows these units to be placed underground and insulated (if needed). In addition, this external cover act as axial guides (higher bellow stability) and anti-torsional devices (higher lifetime of the bellows).

- Internal Protection, using an inner sleeve which avoids the internal surface of the bellows to be damaged by any possible erosive particle present in the system.

- Maintenance free.

- Long life expectancy.

- Anti-torsion.

These units can be equipped with optional accessories such as movement indicators, movement limiters, blocking devices, etc.

MACOGA is a leading supplier of District Heating Expansion Joints.

MACOGA District heating expansion joints can be externally insulated like pre-insulated pipes by applying insulation on the external cover.