MACOGA Site Staff of expert technicians provide needs-based and solution-oriented services for any specific need of each plant or customer. We have extensive training experience in a wide variety of industries including power generation, nuclear, pulp and paper, steel, water, wastewater, chemical/petrochemical and refineries.

With over 40 years of experience, our team of highly skilled technicians deliver and execute an unrivalled range of services to the highest standards of safety, quality and reliability.

When critical equipment fails, no matter whether it’s day or night, on a weekend or during the week, it must be fixed.

From the simplest inspection to the most complex assembly or repair in operation we understand the importance of being there when our customer needs us.

We operate 24 hours a day, 365 days a year in order to provide our customers with a level of service that is unrivalled.

Our technicians will go anywhere. We operate globally providing a range of engineering solutions and on-site services to meet customers' expectations. We have carried out countless successful interventions in more than 50 countries around the world.

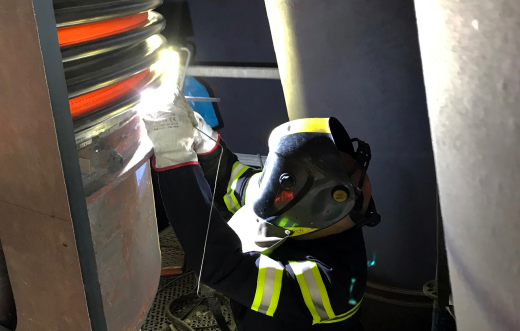

We have the best onsite Field Engineers and Technicians with an excellent combination of experience and technical skills.

We provide one or more of our qualified Field Engineers with a team of Highly-qualified Technicians to perform any work onsite, whether is simple inspection or the most complex repair or installation.

Our Field Engineers are trained and experienced to install any type of Expansion Joint according to specifications and have leadership skills to manage a highly specialized team of technicians, welders, etc.

An emergency repair is something that needs to be fixed quickly because it is a danger to health, safety or plant operation.

Minimizing downtime is the number one priority. We have the capacity to design and manufacture any Expansion Joint in a record time and we have always the best team of professionals to travel anywhere in the world to replace or repair a damaged unit.

No matter your industry or application, our on-site team is highly specialized in repairing damaged Expansion Joints and is available 24 hours a day, seven days a week.

If a bellows is leaking or damaged, or if a bellows must be changed with a target to having the minimum downtime, this is where a clamshell should be considered.

MACOGA Clamshell bellows is the best solution when a quick and unexpected replacement of the bellow is necessary. Clamshell bellows is a two-piece bellow which is welded around the existing unit.

The bellows is split in half longitudinally in our works. The halves are match-marked to ensure the bellows halves are aligned correctly. The clamshell is fitted accurately in position. A purge gas is set up to minimize oxidizing of the weld to ensure a good quality weld. The clamshell halves are then welded back together.

More information

Our team of qualified Engineers provides expert guidance and oversight during the assembly and installation of Expansion Joints, as well as thorough site inspections to assess their condition. We offer pre-assembly guidance, periodic inspections, and a final inspection upon completion to ensure proper procedures are followed.

Our experienced professionals thoroughly examine your expansion joints, evaluating material quality, movement capacity, performance, and signs of wear or damage.

We provide a comprehensive report detailing the condition of each joint, including observations, photographs, and maintenance or replacement recommendations, prioritized by urgency.

Our experts offer guidance on maintaining and extending your expansion joints' lifespan, optimizing efficiency and durability.

We tailor inspections to address your specific concerns about the expansion joints on-site.

The site inspection for expansion joints typically involves several essential steps to ensure a comprehensive and accurate assessment. Here's an overview of the process:

We gather information about your expansion joints, installation history, and specific concerns.

Our team conducts an on-site visual inspection, checking for wear, damage, leaks, corrosion, etc.

When necessary, we use NDT techniques to uncover hidden defects.

Critical joints may undergo load and stress analysis to ensure they can handle required stresses.

We document findings and record relevant data for each joint.

A detailed report includes findings, descriptions, risk assessments, and maintenance or replacement recommendations.

We prioritize actions based on severity and potential risks.

We present the report, explain findings, and provide expert advice.

We offer ongoing support for maintenance, repair, or replacement.

You can use the report to take necessary actions for maintenance and safety.

In our reports for expansion joints inspection, the following information can be expected to be included:

An overview of the inspection, including the purpose, scope, and objectives.

Information about the customer's facility, installation date of the expansion joints, and any specific characteristics of the site.

A description of the inspection methods used, such as visual inspection, non-destructive testing techniques, load and stress analysis, etc.

A concise summary of the overall condition of the expansion joints, highlighting any significant issues or areas of concern.

A section dedicated to each individual expansion joint, providing a detailed analysis of its condition. This may include:

a. Visual Inspection Results.

b. Non-Destructive Testing Results: If applicable.

c. Load and Stress Analysis Results: If conducted

An evaluation of the potential risks associated with each expansion joint's condition, indicating the level of urgency for maintenance or replacement.

Clear and actionable recommendations for each expansion joint, which may include:

a. Immediate actions required for critical issues

b. Short-term maintenance measures to address minor problems and prevent further deterioration.

c. Long-term strategies for replacement or major repairs, with suggested timelines.

Images of the expansion joints, highlighting specific areas of concern and providing visual evidence to support the findings.

A summary of the key findings, risk assessment, and proposed actions.

Additional technical data, charts, or diagrams that may be relevant to the inspection and its findings.

We provide you with a comprehensive assessment, actionable recommendations, and ongoing support to ensure the reliability of your expansion joints.

If required, a site-specific erection plan is developed during one or more pre-construction conferences and site inspections involving the customer, the contractor, and others such as the project engineer.

MACOGA Expansion Joints are certified by the world’s leading classification authorities.

From design to final tests and shipping, all production phases are regulated in accordance with the requirements of the MACOGA’s Quality, Health, Safety and Environment management system.

MACOGA has type approved Expansion Joints available certified with:

We provide our customers safety and reliability through a certified quality management system.

Additionally, MACOGA holds numerous industry approvals, including: