Introduction

A Tank Farm, also known as an oil terminal or oil depot, is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other storage facilities

Tank farms typically have a variety of above or below ground tanks and also include all the equipment used during the storage of liquids and gases for inter-tank transfer, pumping stations, loading gantries for filling road tankers, ship loading/unloading equipment at marine terminals and pipeline connections.

Storage tanks are available in various sizes and shapes depending on the nature of liquids or gases they hold. Some storage tanks require floating roofs in addition to the fixed roofs.

There are three general types of aboveground storage tanks used in the petroleum and petrochemical industries. They are selected based on the service intended and the flash points of the content. These tanks include fixed roof, external floating roof, and internal floating roof.

When a tank is filled, the added weight causes it to sink into the ground and a bulging of the inner wall of the tank occurs.

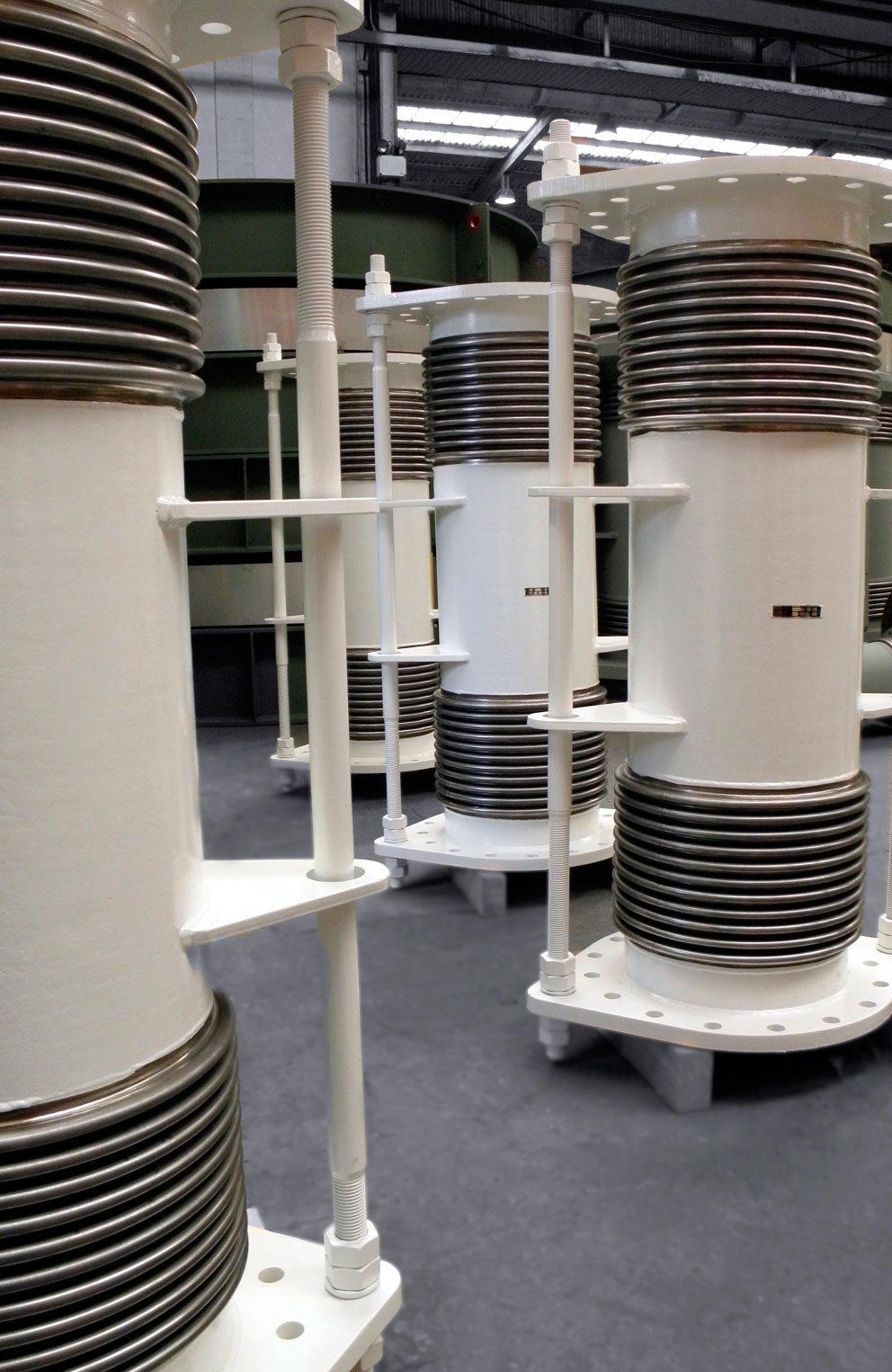

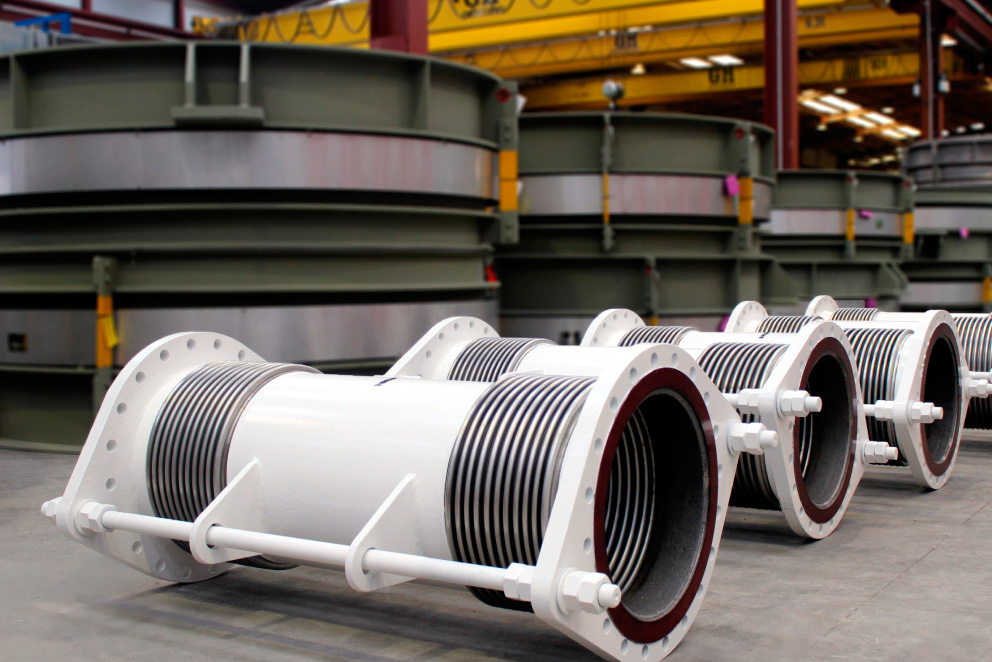

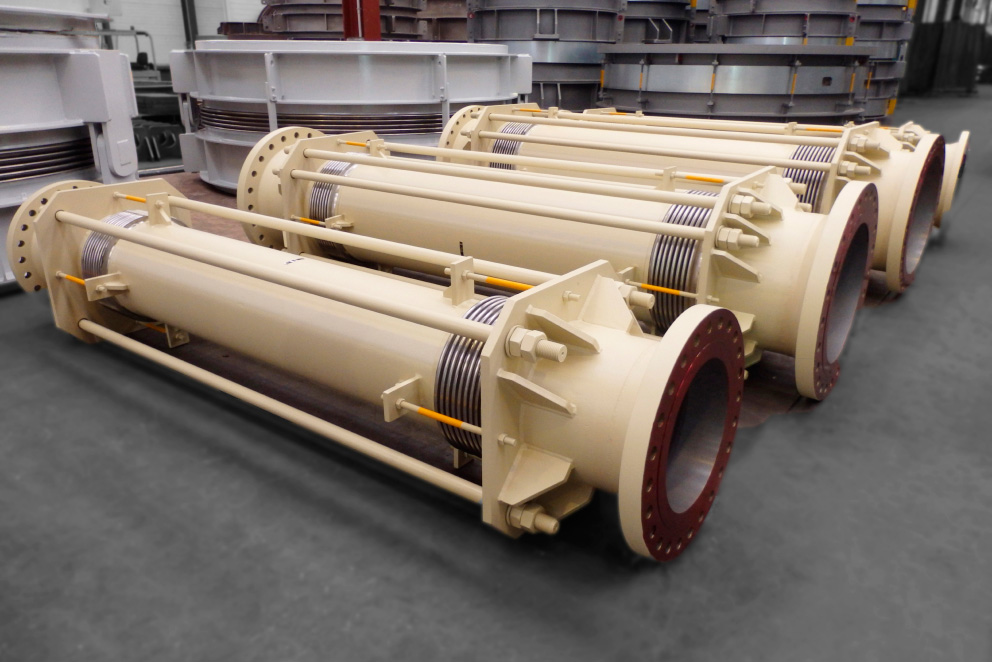

To compensate for these tank movements generated during the different filling and emptying processes, it is necessary to install expansion joints in the tank connections to the pipes.