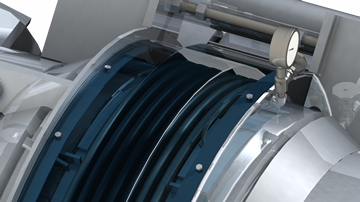

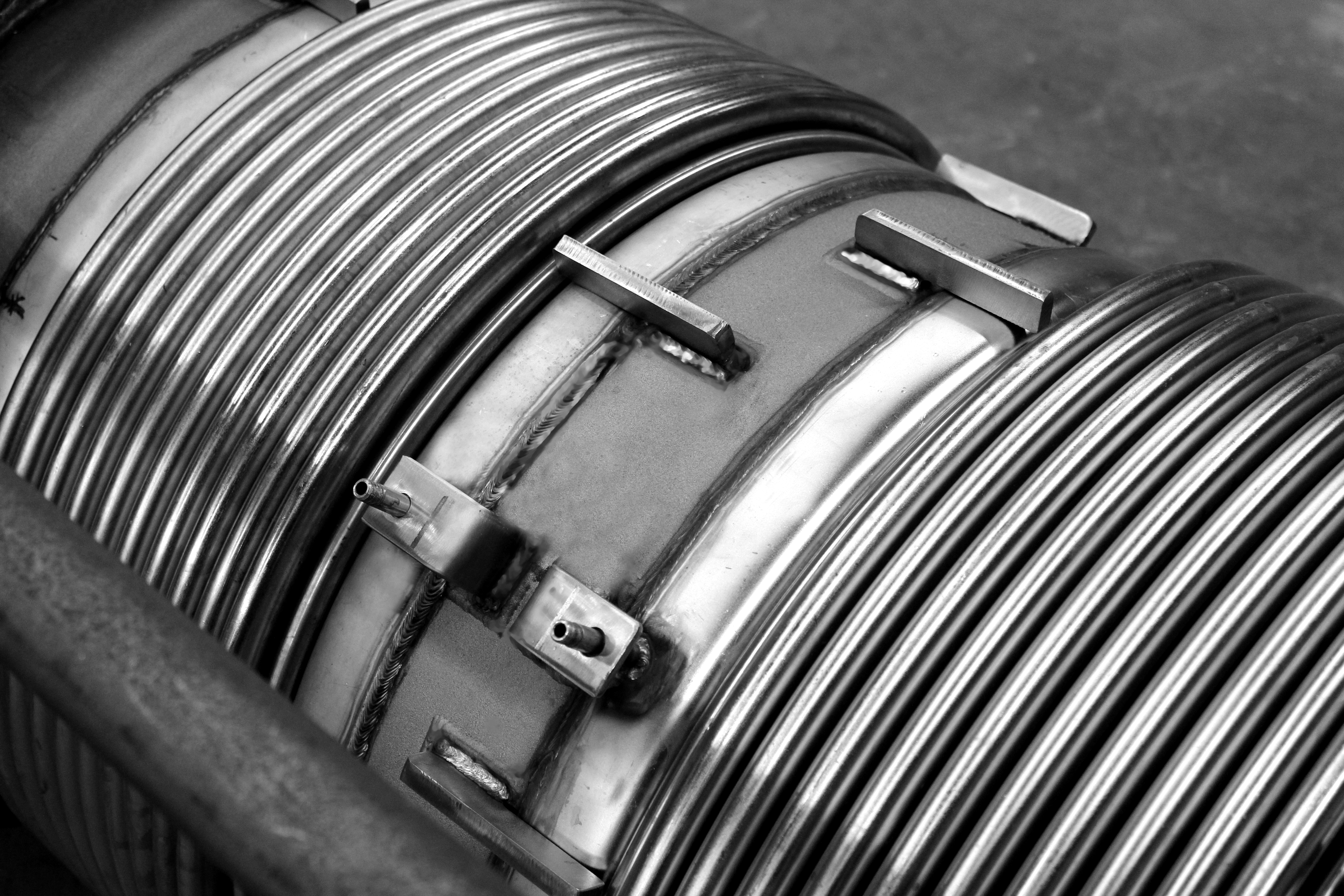

The bellows, as the most critical part of the Expansion Joint, can be single ply, multiply, redundant ply or reinforced.

In two ply testable bellows each ply is designed for the full operating conditions (pressure, temperature and movements).

If a hole or stress crack develops in the inner ply during service, the outer ply takes over without exposing operators to increased risk or creating the need for an unscheduled shutdown.

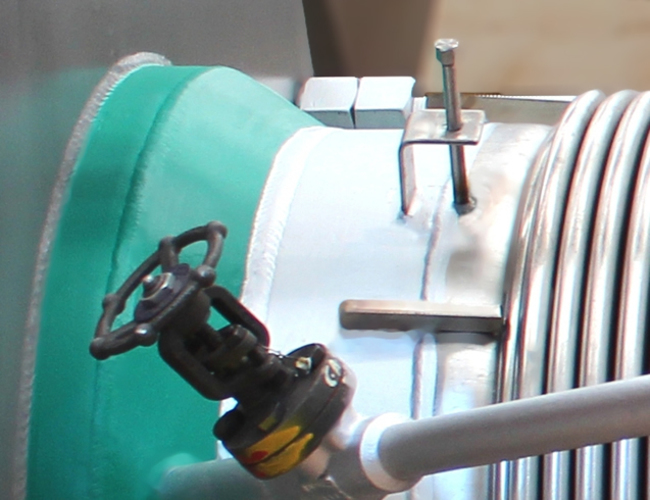

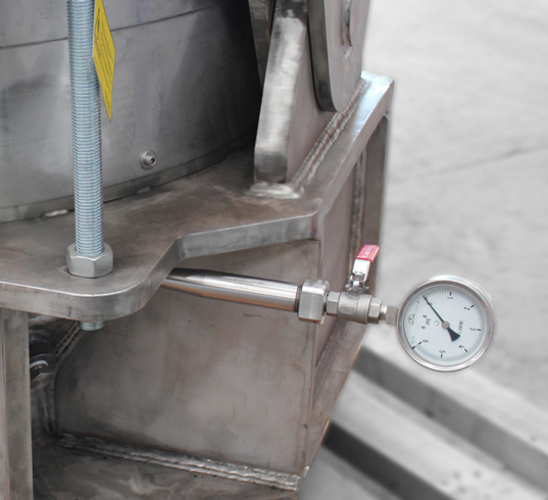

In monitored ply bellows the annular space between plies can be monitored for leakage to detect a ply failure. This will serve as a warning of an imminent problem. A pressure device in the outer ply alerts about the inner ply failure. The two ply testable bellows also allows inspectors to pressure test the inner and outer ply during shutdowns.

Two ply testable bellows system improves reliability, in most of cases provide early warning about bellows failure and makes the expansion joint more maintenance friendly.

Refineries generally use two-ply testable bellows especially in critical process equipment such as the FCC unit.