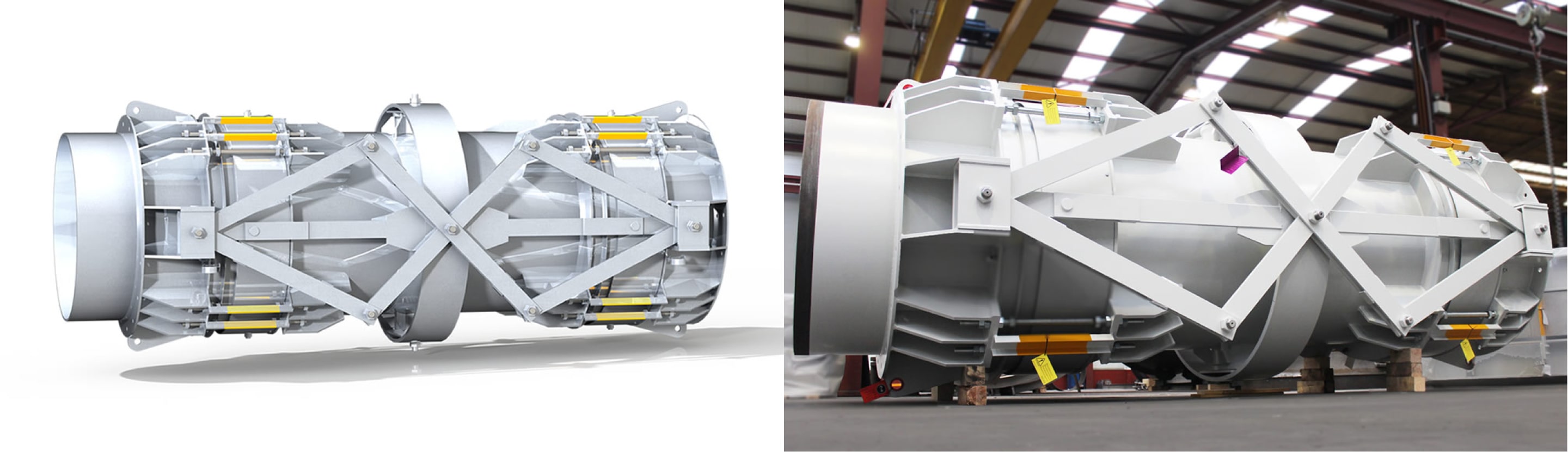

At MACOGA we use the most advanced calculation and design tools that guarantee a successful performance of our Expansion Joints from the very beginning.

Services

Design & calculation

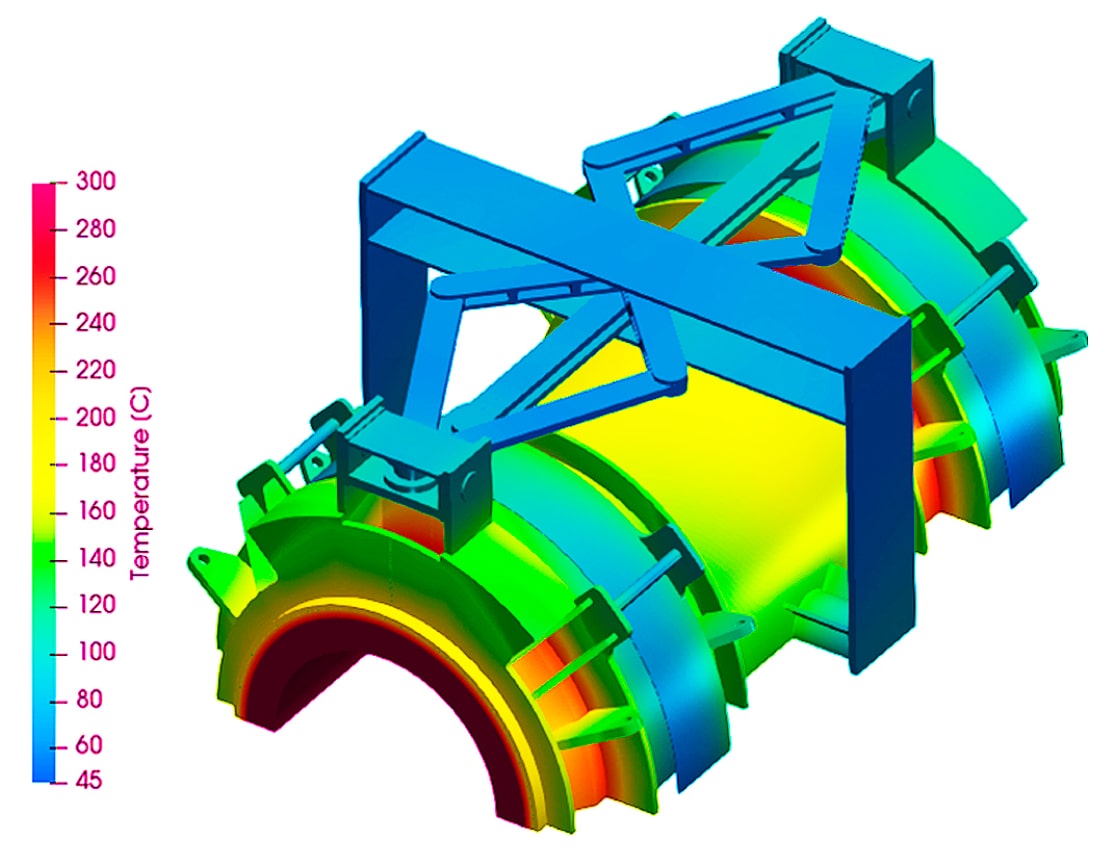

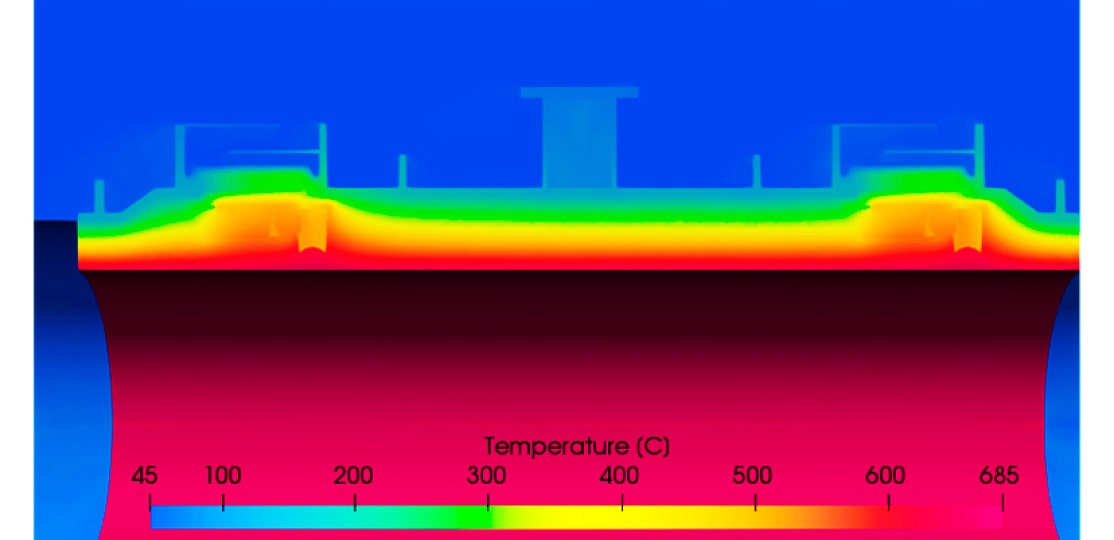

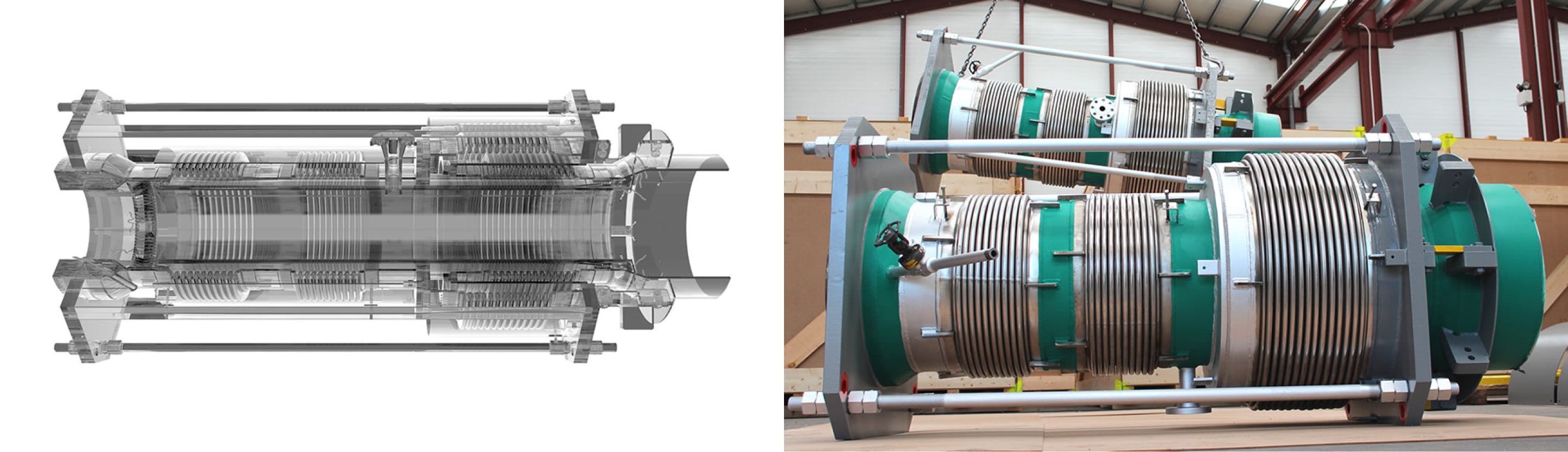

Our engineers are equipped with the necessary tools to gain insight into the key factors for quality and performance at an early stage of product development. Digital prototyping coupled with digital analysis and simulation allows our engineers to virtually create and analyze an Expansion Joint and all its components in their operating environment.