Reducing expansion joints are designed and manufactured to allow the connection of different diameter pipes. There are two main types of reducer: concentric and eccentric reducers. Reducers are usually concentric but eccentric reducers are used when required to maintain the same top -or bottom of- pipe level.

The non-standard “Offset” rubber expansion joints are designed and fabricated in consideration for installation misalignment and non-parallelism, of the attachment piping axis. The “Offset” joints are often used in restricted spaces where use of standard piping is not feasible for correction of misalignment.

Please note that Macoga typically drills flanges in accordance with the flange pipe size, when specific instructions are not provided by customer. Because these are custom units, Macoga suggests that details of construction either in fabrication drawings or detailed specifications, be provided with the request for quotation on “Offset” Rubber Expansion Joints.

Macoga rubber expansion joints are available in many standard pipe sizes with fluoroplastic lining of PTFE and/or FEP. These lining is fabricated as an integral part of the expansion joint during manufacture and cover all wetted surfaces in the tube and flange areas. Fluoroplastic provides exceptional resistance to almost all chemicals within the temperature range of the expansion joint body construction.

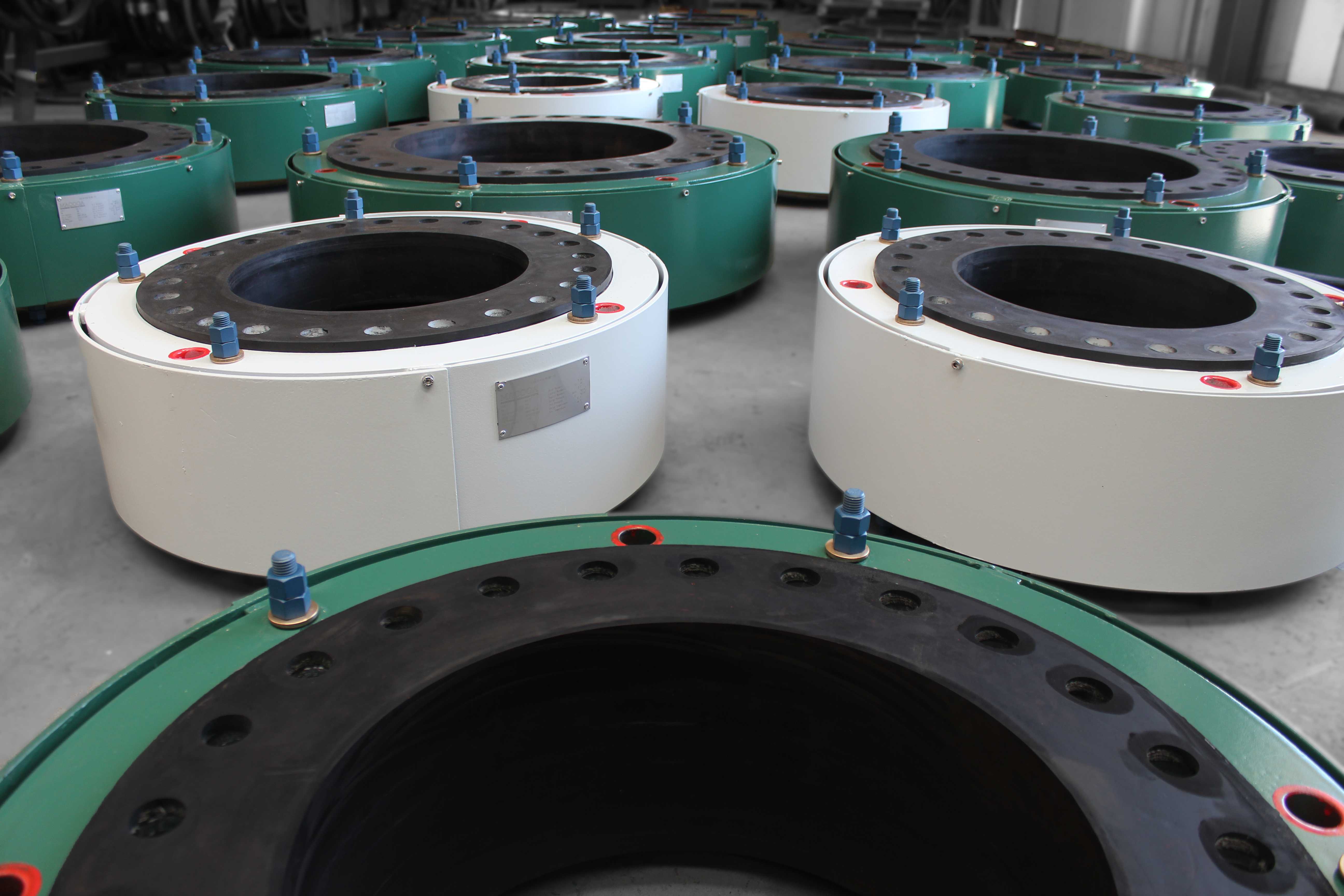

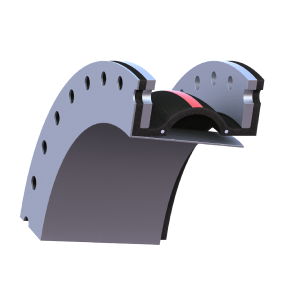

Split metal retaining rings are also in our range of production. The rings are installed directly against the back of the flanges of the expansion joint.

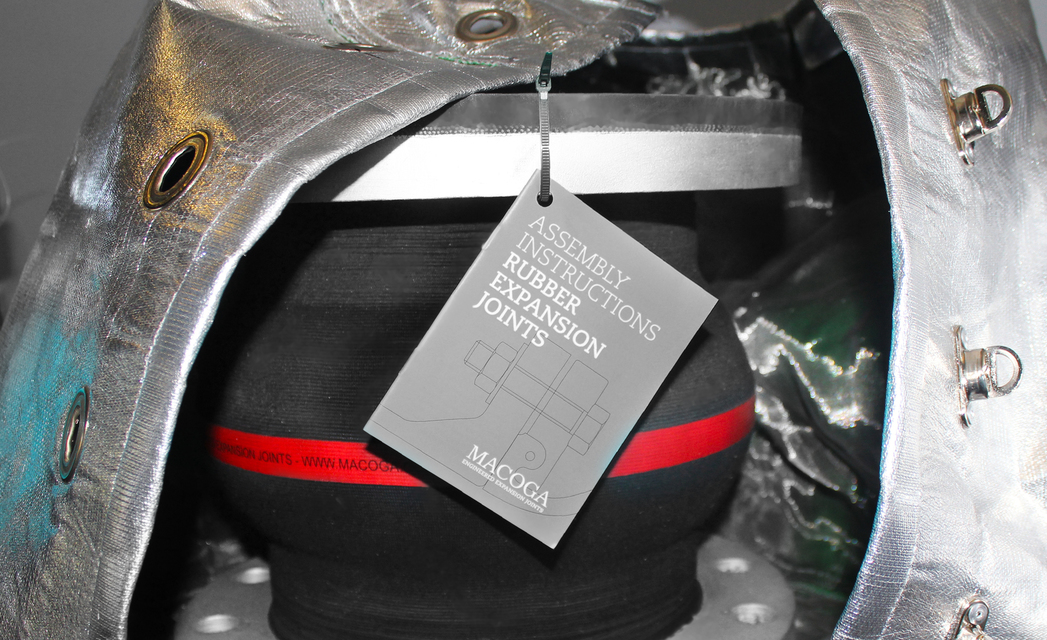

Protective covers of expanded metal are used to prevent exterior damage to the expansion joint. Fire covers, designed oversize, are insulated on the I.D. to protect the expansion joint from rupture during a flash fire. They are normally installed on fire water lines.

Sun covers protect the elastomer against UV radiation. When possible, it is not recommended to insulate over elastomeric expansion joints.

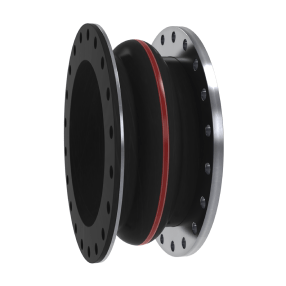

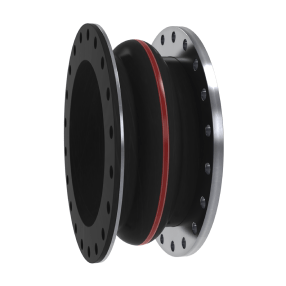

Expansion joints with two or more arches (convolutions) may be manufactured to accommodate movements greater than those of which a single arch type joint is capable of.Length of the joint is dependent on the number of arches.

This solution is used when the holes of the mating flanges in the pipes are not aligned and there is no possibility of align them.

There are cases that on-site installation of the tie rods could be the best solution, specially when the expansion joint is connected directly to an equipment. Make sure that there is sufficient clearance behind the connecting flange.

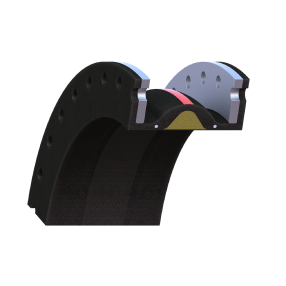

Filled arch-type expansion joints may be supplied with a bonded-in-place soft rubber filler to provide a smooth interior bore. Filled arch design reduces possible turbulence and prevents the collection of solid materials that may settle from the solution handled and remain in the archway. Filled arch joints also have a seamless tube so the arch filler cannot be dislodged during service.

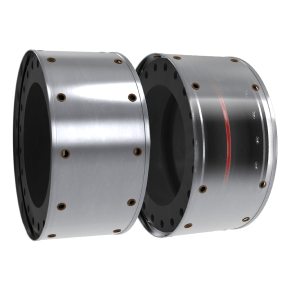

Consists of a sleeve extending through the bore of the expansion joint with a full-face flange on one end. Constructed of hard rubber, metal or fluoroplastic it reduces frictional wear of the expansion joint and provides smooth flow, reducing turbulence. This type sleeve should not be used where high viscosity fluids, such as tars, are being transmitted. These fluids may cause packing-up or caking of the arch area, which reduces movements and in turn may cause premature expansion joint failure.