Metal Expansion Joints main parts and accessories

The basic unit of every expansion joint is the bellows. By adding additional components and accessories, the complexity and capability of the expansion joints is increased making them suitable for a wide range of applications and services.

These are some of the main and basic Expansion Joints accessories and components.

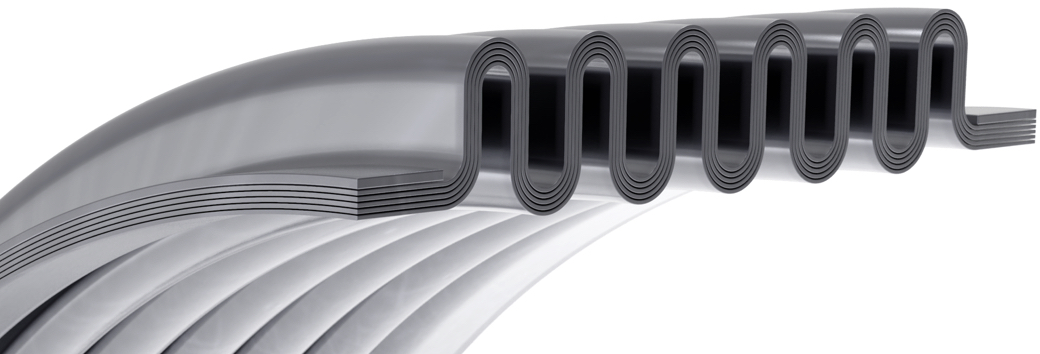

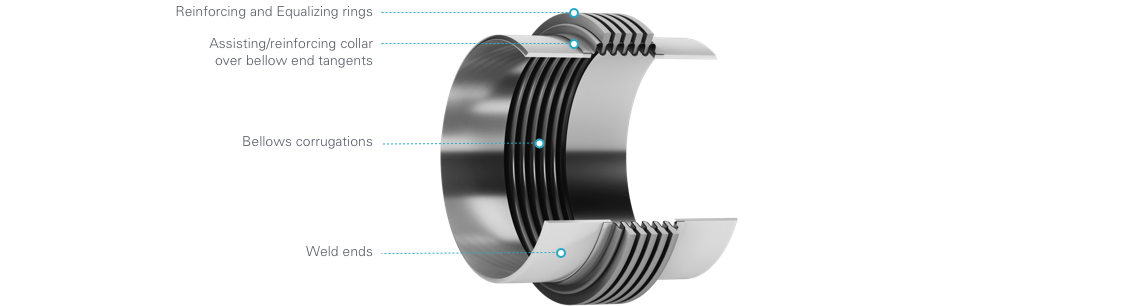

Bellows

A flexible element consisting of one or more corrugations and the end tangents.

The bellows can be singleply or multiply.

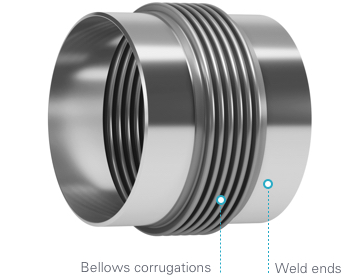

End tangents

The straight un-convoluted portions at the end of the bellows.

Connections

The most common types of connection parts are weld ends or flanges. In some cases male or female threaded ends are used.

Weld ends

The ends of an expansion joint equipped with pipe for weld attachment to adjacent equipment or piping. Weld ends are commonly supplied beveled for butt welding.

Flanged ends

The ends of an expansion joint equipped with flanges for the purpose of bolting the expansion joint to the matting flange of adjacent equipment or piping.

Flanged ends can be supplied fixed or swivel.

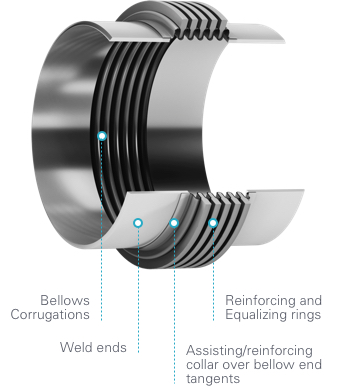

Reinforcing collars

Reinforcing sleeve or ring attached to the end tangent for reinforcement.

Assisting collar

Ring placed around the end tangents to facilitate welding.

Reinforcing and equalizing rings

Devices fitting snugly in the roots of the corrugations in order to reinforce the bellows against internal pressure, and/or to distribute axial movement equally to all convolutions while limiting amount of compression movement per convolution.

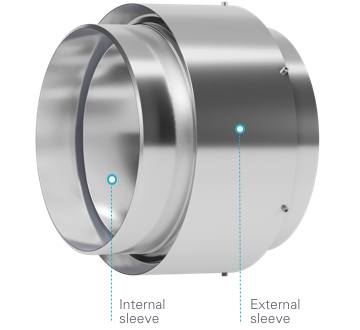

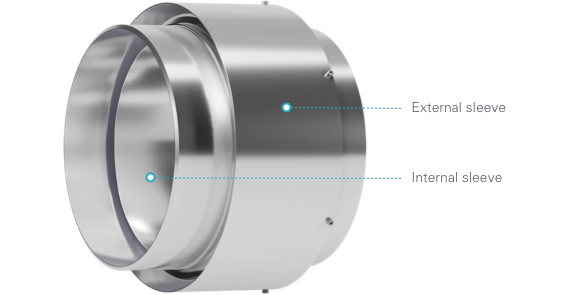

Internal sleeve

A device which minimizes contact between the inner surface of the bellows of an expansion joint and the fluid flowing through it. These devices have also been referred to as liners or baffles.

Internal sleeves shall be specified for all Expansion Joints in the following cases:

- When flow velocities are high and could induce resonant vibration of the bellows.

- When it is necessary to hold friction losses to a minimum and smooth flow is desired.

- When there is a possibility of erosion, as in lines carrying catalyst or other abrasive media, heavy gauge sleeves must be used. At no time should the relatively thin bellows be directly exposed to erosion.

- When there is reverse flow, heavy gauge sleeves may be required, or the use of telescopic sleeves may be appropriate.

- For high temperature applications to decrease the temperature of the bellows and enable the bellows metal to retain its higher physical properties. The annular area between the bellows and liner may be packed with ceramic fiber insulation, or a gas purge may be installed to further reduce the bellows effective temperature.

External cover or external sleeve

A device used to provide external protection to the bellows form foreign objects, mechanical damage and/or external flow and may act as a support for external thermal insulation.

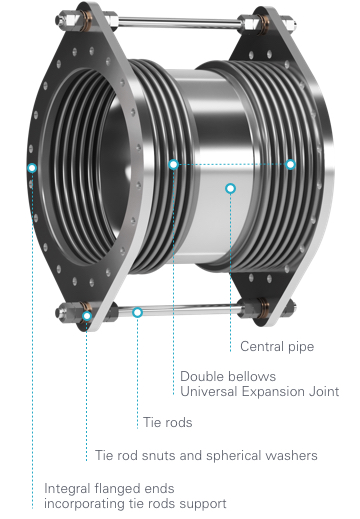

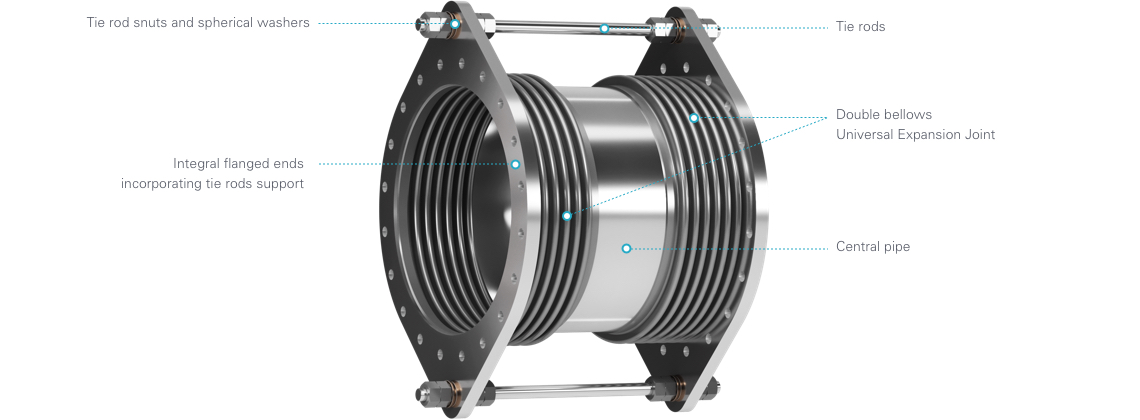

Tie rods

Devices, usually in the form of rods or bars, attached to the expansion joint assembly whose primary function is to continuously restrain the full bellows pressure thrust during normal operation while permitting only lateral deflection. Angular rotation can be accommodated only if two tie rods are used and located 90° opposed to the direction of rotation.

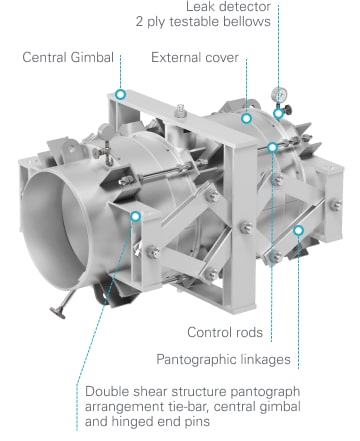

Control rods

Devices, usually in the form of rods or bars, attached to the Expansion Joint assembly whose primary function is to distribute the movement between the two bellows of a universal Expansion Joint. Control rods are not designed to restrain bellows pressure thrust.

Limit rods

Devices, usually in the form of rods or bars, attached to the expansion joint assembly whose primary function is to restrict the bellows movement range (axial, lateral and angular) during normal operation. In the event of a main anchor failure, they are designed to prevent bellows over-extension or over-compression while restraining the full pressure loading and dynamic forces generated by the anchor failure.

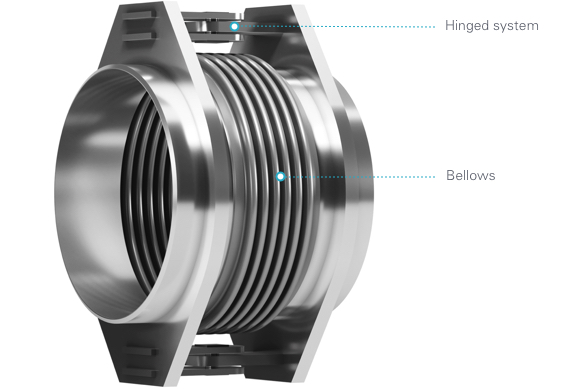

Hinged System

Hinged Expansion Joints incorporate a system of articulated supports (a pair of pins through hinge plates attached to the pipe expansion joint ends) which allow for angular movement in one plane only. The hinges and hinge pins must be designed to restrain the thrust of the Expansion Joint due to pressure and extraneous forces, where applicable.

These units do not allow axial movement however, some types of hinge systems can be provided with holes for the hinge pin that are slotted to allow limited axial displacement. These “slotted hinge” types cannot resist the pressure thrust forces and therefore proper anchorage must be provided.

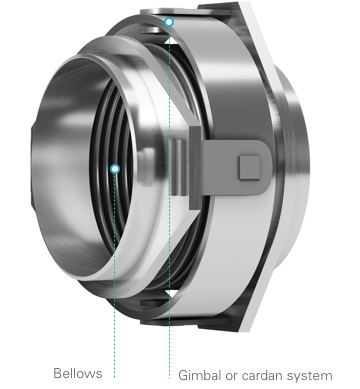

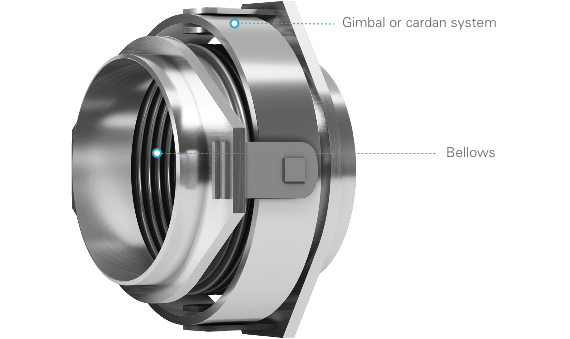

Gimbal or Cardam System

The gimbal system consists in two pairs of hinges affixed to a common floating gimbal ring.

A gimbal ring is either round or square. For round gimbals the torsional moment shall be considered and for square gimbals the instability due to the bending shall be considered.

Gimbal Expansion Joints are designed to allow angular movement in any plane and the gimbal ring, hinged and pins are designed to restrain the pressure thrust due to internal pressure and shear forces.

Pantographic linkages

A scissors-like device. A special form of control rod attached to the expansion joint

assembly whose primary function is to positively distribute the movement equally

between the two bellows of the universal joint throughout its full range of movement.

Pantograph linkages, like control rods, are not designed to restrain pressure thrust.