Main features of MACOGA Metal Bellows

- From 15 mm up to 10 meters diameter

- Single ply or Multiply construction

- Reinforced and unreinforced

- Available in austenitic stainless steel, duplex, nickel alloys, low alloyed steels, titanium,

- carbon steel, etc.

Main parts of metal bellows

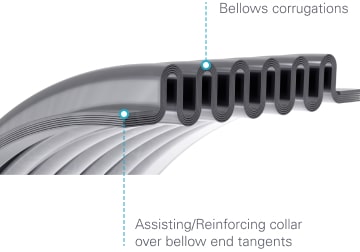

Corrugation or convolution

Flexible unit of a bellows with a leakproof wall consisting of one or more plies. Ply element of the bellows’ wall usually made from sheet or strip material.

End tangent

Straight un-corrugated portion at the ends of a bellows.

Assisting and reinforcing collar

Ring placed around the end tangents for reinforcement and to facilitate welding.