Introduction

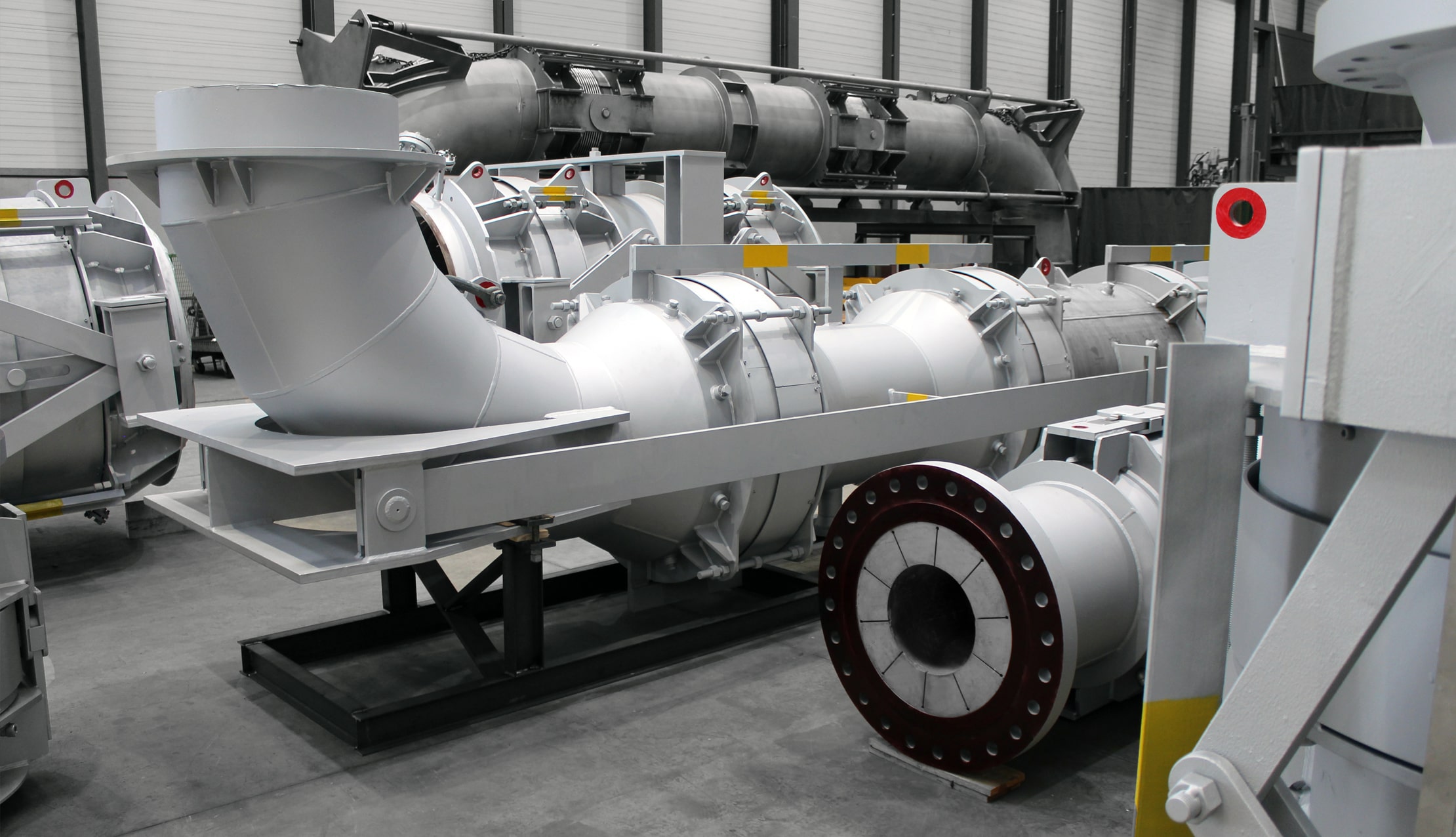

Expansion joints used in FCCU service are exposed to high temperatures, high pressures, large movement conditions and very aggressive media and therefore they are considered highly engineered units and one of the most critical and complex types of expansion joints manufactured.

The design of these expansion joints is complex because:

- They must be suitable to operate at high process temperatures

- They must be resistant to erosion by catalyst

- They must be resistant to corrosion and stress corrosion cracking during operation and shutdown conditions

- They shall ensure an adequate fatigue life

- They must absorb large movements

- They shall ensure a good pressure resistance capacity while having a good flexibility

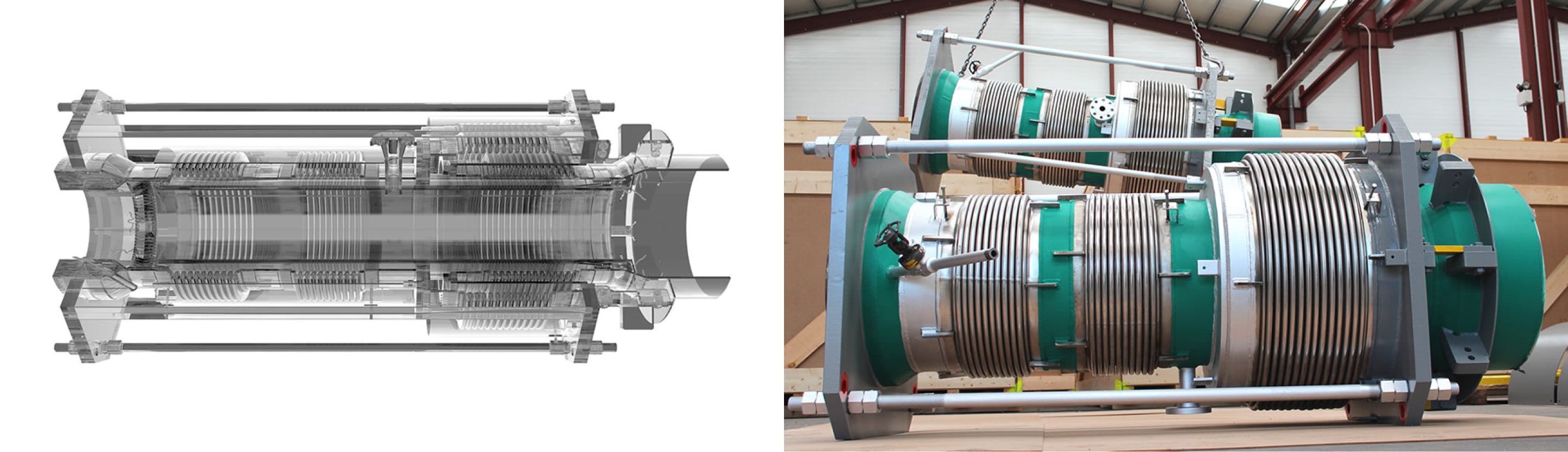

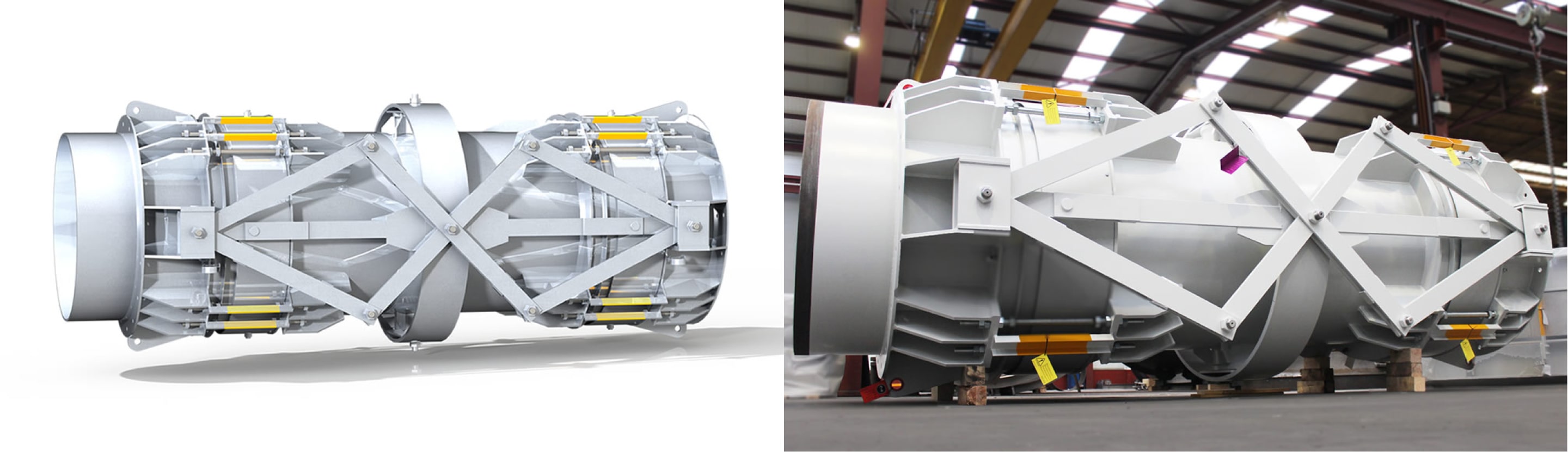

MACOGA has advanced capabilities to design and analyse FCCU Expansion Joints and all its components and accessories operating at high temperatures. Our analysis tools, e.g. non-linear finite element stress and heat transfer analysis (FEA) make possible to analyse complex components.

With our 3D mechanical CAD software our engineers design FCCU Expansion Joints to the same conditions that they’ll experience in the real world before they have been built. This is a design validation tool that helps our engineers to test the designs earlier in the design cycle and against real-world conditions. This lead us to improved design quality and manufacturing efficiency, while reducing time to market, costs and materials waste.

FEA/CFD

Our engineers are skilled in using Finite Element Analysis (FEA) and Computer Fluids Dynamics (CFD) to analyze the thermal-mechanical performance of different kind of systems.

Finite Element Analysis (FEA) based structural stress analysis is a valuable tool in the evaluation and optimization of product designs for systems including structural stress due to mechanical and thermal loading.

Using FEA/CFD as part of your product design process allows for the rapid and cost effective virtual testing and optimization of your designs. This will reduce overall product development costs, improving design performance and also give your team greater insights into how your design is likely to respond to a range of operating conditions.

Some samples of FEA/CFD studies:

- Design/Analysis to ASME, API, PD and UNE standards

- Stress analysis

- Thermo-mechanical analysis

- Heat transfer

- Fatigue

- Vibration Analysis

- Dynamic analysis

- Shock analysis

- Resonance analysis

- Coupled fluid structure interaction

- HVAC analysis