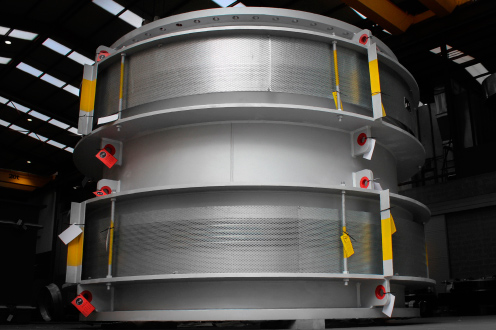

Steelmaking uses a huge variety of metal Expansion Joints in a multitude of applications.

In steel plants there are many metal expansion joints installed and its principal use is in the blast furnace, converter, relief lines, staves, coke gas lines, combustion lines, gas cleaning system and other pipelines.

Steelmaking facilities demand Expansion Joints capable of handling high temperatures and aggressive media.

At every step of the steel making process, reliable Expansion Joints are required to handle industrial gasses, steam, water, lime and other process media. MACOGA provides customized Expansion Joints for every process of steel production, from iron making to steel making, continuous casting and rolling, as well as power plant and oxygen plant.

MACOGA offers a complete range of Expansion Joints for any Steel Plant applications and all our Expansion Joints combine the latest technologies with decades of industry expertise in all areas of steel production.

MACOGA is today the world leader in the design and supply of Expansion Joints for the iron & steel industry: Blast Furnaces & Auxiliary Plants, Coke Making Plants, Direct Reduction Plants, etc.

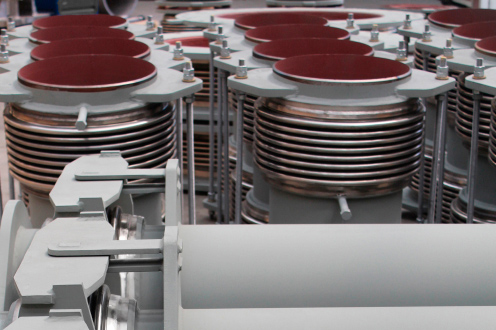

MACOGA Expansion Joints are certified by the world’s leading classification authorities.

From design to final tests and shipping, all production phases are regulated in accordance with the requirements of the MACOGA’s Quality, Health, Safety and Environment management system.

MACOGA has type approved Expansion Joints available certified with:

We provide our customers safety and reliability through a certified quality management system.

Additionally, MACOGA holds numerous industry approvals, including: